Modular vs Stick Built House: An Expert Guide for North Carolina Homeowners

Deciding between a modular and a stick-built house is a huge call to make. It feels massive because, well, it is. The core difference is pretty straightforward: modular homes are built in sections inside a factory, while stick-built homes are constructed entirely on your property, piece by piece. As local leaders in the Fayetteville and Lumberton communities, our team at South Eastern General Contractors (SEGC) understands this choice ripples through everything—your budget, your move-in date, and the legacy you're building for your family.

The Two Paths to Your Dream Home

Figuring out how to build your home, especially in communities like Fayetteville or Lumberton, is about more than just picking a construction style. It's about choosing the right path for your family's future. For over 21 years, we at SEGC have walked families through this exact decision. As a Native American-owned, 8(a), and HUBZone certified firm, our commitment to client trust and quality is the foundation of every project. We don’t just put up walls—we help build legacies.

Let's pull back the curtain on these two popular building methods.

A stick-built home is what most people picture when they think of home construction. A foundation gets poured, and then the house is framed, sheathed, and finished right there on the land. This classic approach gives you almost total architectural freedom, but it also leaves your project at the mercy of the weather and can lead to more material waste on-site.

A modular home, on the other hand, is a masterclass in efficiency. The house is built as separate modules inside a climate-controlled factory. This means your foundation can be prepared on-site at the same time your home is being built indoors. It’s a parallel process that seriously cuts down the timeline and tightens up quality control, delivering predictable results you can count on.

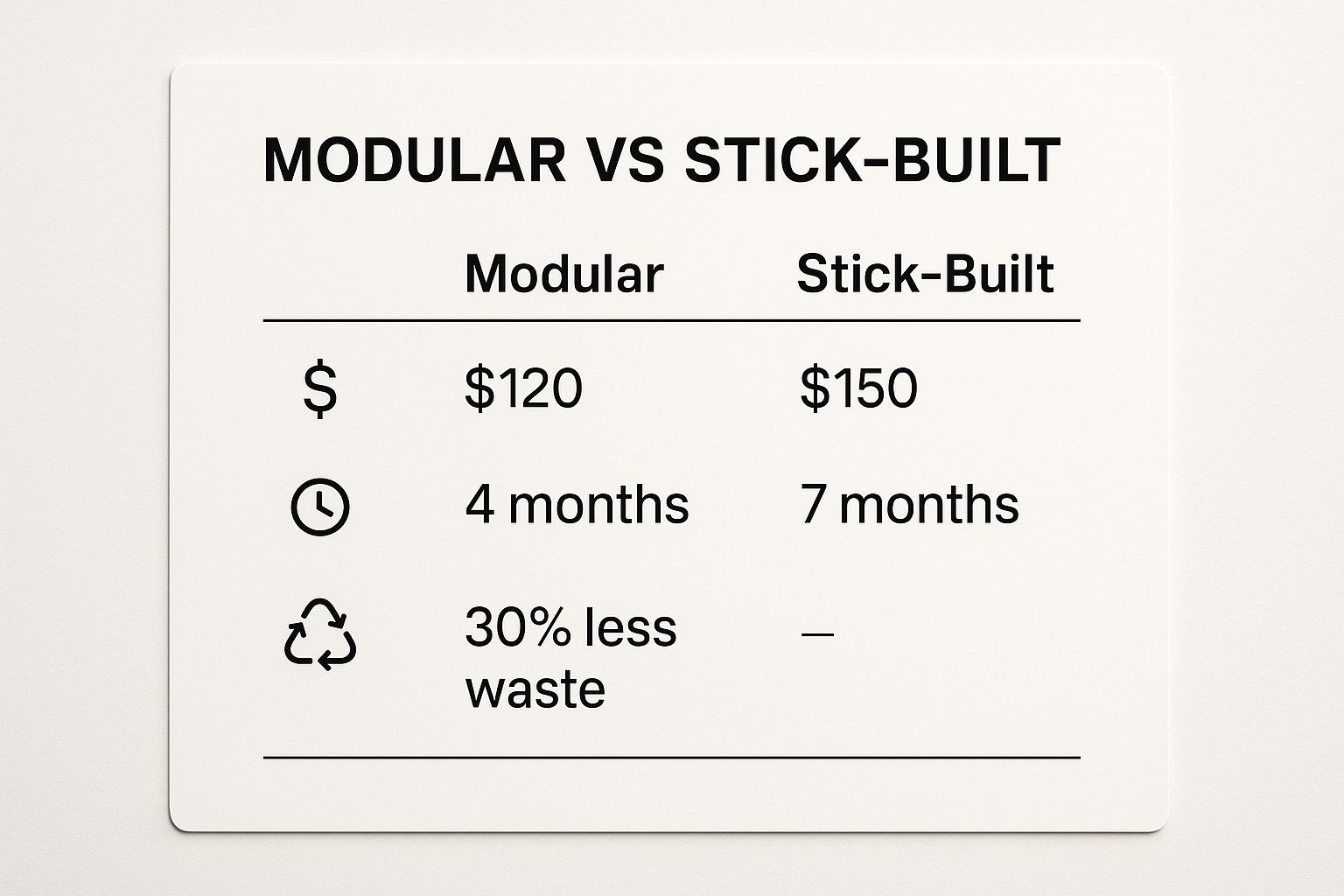

This infographic breaks down some of the key numbers when it comes to cost, timing, and waste.

As you can see, that factory-controlled environment often translates into real savings in time, money, and materials—actionable insights that empower you to make a smarter choice.

To give you a clearer picture, here's a quick side-by-side look at the two options.

At-a-Glance Modular vs Stick-Built Homes

| Factor | Modular Home | Stick-Built Home |

|---|---|---|

| Construction Method | Built in factory-controlled sections, then assembled on-site. | Built entirely on-site from the ground up, piece by piece. |

| Average Timeline | Typically 3-5 months from start to finish. | Generally 6-12+ months, susceptible to weather delays. |

| Design Flexibility | Highly customizable with a wide range of floor plans and finishes. | Offers virtually limitless customization and unique architectural designs. |

| Quality Control | High, due to factory precision, consistent standards, and indoor inspections. | Varies depending on the skill and oversight of on-site trade crews. |

| Sustainability | Generates up to 30% less material waste due to efficient factory processes. | On-site construction can lead to significant material surplus and waste. |

This table lays out the basics, but the best choice for you really depends on what you value most. Below, we'll dive deeper into these factors to help you weigh the pros and cons for your specific situation.

A Tale of Two Timelines: How Each Home Gets Built

Imagine two new homes breaking ground on the exact same day. The first is a traditional stick-built home, where everything starts and ends right there on your plot of land in Fayetteville. The second is a modular home, and its story begins in two places at once: a specialized factory and your future front yard. This parallel construction is the secret sauce that completely changes the building game, providing an actionable advantage in your construction journey.

For a stick-built house, the process is linear, one step following the next, and completely at the mercy of Mother Nature. The lumber shows up, the framing crew gets to work, and your home slowly takes shape, nail by nail. It’s a classic, time-honored process, but progress can grind to a halt with a single bad forecast or a scheduling snafu between subcontractors.

A modular home, on the other hand, comes together with the kind of precision you only get from a factory floor. While our SEGC team is on your property in Lumberton expertly prepping the site and pouring the foundation, your home's individual modules are being assembled indoors. Think walls, flooring, plumbing, and electrical—all installed in a climate-controlled facility, keeping materials in perfect condition and the schedule locked in.

The On-Site Reality: A Local Example

A recent SEGC project right here in Fayetteville really brings this difference to life. We started the foundation work, which took a few weeks of on-site prep and curing. At the very same time, the modules for the house were being meticulously built in the factory. By the time the foundation was rock solid and ready, the modules arrived on trucks, already 85% complete. One of our clients, a teacher in the Cumberland County school system, was amazed that she left for work in the morning with a bare foundation and came home to a nearly complete house. That's the power of this process.

This dual-path approach absolutely slashes the overall construction timeline. We're not waiting around for framers to clear out so the electricians can begin; most of that interplay has already happened. The on-site work shifts from a ground-up build to a process of expert assembly, connecting the utilities, and applying the final custom touches.

“The biggest surprise for our clients is seeing their home take shape in a single day. When the modules arrive and are set by the crane, what was an empty foundation in the morning becomes a recognizable house by evening. That moment is where the efficiency of modular building really hits home.” – Johnathan, SEGC Project Manager

Quality Control and Building Materials

The differences between a modular vs. a stick-built house don't stop at the schedule; they carry right through to the materials and quality oversight. Building a modular home in a factory setting means less waste and a chance for constant, eagle-eyed inspections at every single stage. That controlled environment also means no rain-soaked lumber or weather damage to your building materials.

The precision and quality control baked into this method deliver a fantastic balance of price and durability. While building costs are always shifting, a 2,000-square-foot modular home often packs incredible value.

Here at SEGC, our deep local roots and certifications as a Native American-owned, 8(a), and HUBZone firm are your guarantee of the highest standards, no matter which building method you choose. We’re obsessed with the details, ensuring your home—whether built in sections or stick by stick—is a landmark of quality. To see what's possible, check out our guide on NC custom modular homes.

The Real Deal on Cost and Timeline

When you're staring down the path of building a new home, two questions always jump to the front of the line: "What's this actually going to cost me?" and "How long until I get the keys?" It's easy to get fixated on a simple price-per-square-foot, but that number rarely tells the whole story. The true financial picture involves everything from site prep and unexpected delays to the financing costs that tick up every single month.

This is exactly where the predictable, almost methodical, nature of modular construction starts to look very appealing. Since most of the heavy lifting happens in a controlled, indoor environment, the timeline feels less like a hopeful guess and more like a firm handshake. This gives you a clear, actionable insight into your financial planning.

Getting Real About Project Costs

The price tag on the floor plan is just your starting point. With a traditional stick-built home, the entire budget is at the mercy of the elements and on-site logistics. Imagine a solid week of rain in Lumberton; that’s not just a soggy work site. It’s a direct hit to your wallet through mounting labor fees and extra interest payments on your construction loan.

After more than 21 years of proven results in our local communities, we've gotten pretty good at seeing the whole picture from day one. At SEGC, we lay it all out for you—from digging the first scoop of dirt to installing the last cabinet knob—so you have total financial clarity.

As a Native American-owned and HUBZone certified firm, our foundation is built on trust. That means having an upfront, honest conversation about your budget to make sure there are no last-minute bombshells. We're building for your family's future, not just putting up four walls. That's the SEGC commitment to quality.

The Speed Advantage of Modular Building

The secret to modular’s speed is its parallel workflow. It's a game-changer. While your crew is on-site in Fayetteville pouring the foundation and running utilities, the modules of your home are being assembled simultaneously inside a factory.

- Stick-Built Timeline: This is a classic one-thing-after-another process. You can't frame the walls until the foundation is cured. You can't run electrical until the structure is weather-tight. A typical project can easily stretch from 6-12 months, and that’s before you factor in the inevitable subcontractor no-shows or bad weather.

- Modular Timeline: Building the house while prepping the land slashes the overall schedule. Most modular homes are buttoned up and ready for you to move in within 3-6 months. That's months of rent or mortgage payments on your old place saved, not to mention less interest paid on your construction loan.

This incredible efficiency is a huge reason why the modular home market keeps expanding. People are catching on to the powerful mix of locked-in costs and a faster path to their front door. If you want to really get into the weeds on the numbers, you can explore a detailed cost comparison of modular and stick-built homes we put together.

At the end of the day, knowing what you’ll pay and when you’ll be done provides incredible peace of mind. By taking most of the unpredictable variables out of the equation, modular construction gives you a clear, confident path from groundbreaking to housewarming.

Busting Myths: Let's Talk Quality and Customization

It's time to put an old, stubborn myth to bed: the idea that choosing a modular home means you're stuck with a boring, cookie-cutter box. Maybe that was the case back in the day, but modern modular construction has completely flipped the script. Today, it’s all about bringing your unique vision to life in a high-quality, beautifully crafted home, no matter how it’s built.

When it comes to the modular vs stick built house debate, the quality conversation isn't really about which method is "better." The real story is that the quality of your home comes down to the builder, not the building style. Here at SEGC, our reputation is everything, and it's built on a rock-solid commitment to craftsmanship. That’s a promise we keep on every single project, whether it shows up in sections or is built piece by piece on your land.

Unlocking Your Design Freedom

Look, it’s true that stick-built homes offer practically endless design freedom. If you can dream it up, an architect can draw it, and a talented crew can make it happen. This is the perfect route for those one-of-a-kind architectural masterpieces with wild footprints and truly unconventional designs.

But don't count modular out. The design flexibility in modern modular homes is genuinely impressive. Forget the simple ranch-style boxes of yesterday. Now you can customize floor plans, add soaring ceiling heights, and choose from a whole catalog of luxury finishes—we're talking gourmet kitchens and spa-like bathrooms. The industry has caught up to the demand for personalized, stylish living.

“Quality isn't a byproduct of the construction method; it's a direct result of the builder's standards. As a Native American-owned firm with deep roots in Fayetteville, our name is on every home. That’s our promise of quality to the community.” – Maria, SEGC Founder

This is where our 21+ years of proven results really make a difference. We’ve seen with our own eyes how a well-managed modular build can produce incredible quality. Think about it: building indoors means every joint is sealed perfectly, materials are shielded from rain and heat, and inspections happen at every single stage. This factory precision often creates a much tighter home, which can mean better energy efficiency and lower utility bills for you and your family.

Quality is in the Craftsmanship, Not the Method

At the end of the day, the choice is about balancing your dream design with your timeline and budget. The main thing to remember is this: A home’s quality isn’t decided in a factory or on a construction site—it’s guaranteed by the integrity and skill of your builder.

As an 8(a) and HUBZone certified contractor, we're held to incredibly high standards. We bring that same obsessive attention to detail to every project, making sure your home isn't just a building, but a legacy. Whether it’s a custom stick-built estate in Lumberton or a beautifully efficient modular home right here in Fayetteville, SEGC is all in on building your vision with care and unmatched quality.

Your Home as a Long-Term Investment

Let’s talk about the future. When you decide to build a home, you’re not just making a construction choice—you’re laying the foundation for your family's financial well-being. A question I get asked all the time here in Fayetteville is how a modular home stacks up against a stick-built one as a long-term asset. The good news? The old, outdated stigmas are ancient history.

Modern modular homes are held to the exact same tough local and state building codes as any home built on-site. Appraisers and lenders see them as equals. When it's time to sell, a well-cared-for modular home will appreciate just like a comparable stick-built house. It's a solid investment, period.

Building for Both Wallet and World

The real value of your home isn't just its price tag down the road; it's also about what it costs to live there every single day. This is where the precision of modular construction really shines and pays you back for years. Since the modules are built inside a factory, protected from the elements, the seals are incredibly tight and the insulation is installed perfectly.

What does that mean for you? A seriously energy-efficient home that can slash your monthly utility bills. That's real money that stays in your pocket, month after month, year after year.

As a Native American-owned and HUBZone certified company, we believe building responsibly is non-negotiable. The reduced waste and incredible energy efficiency of modular homes perfectly match our mission to build a stronger economic and environmental future for our communities in Lumberton and Fayetteville. We're not just building structures; we're building legacies.

The Growing Appeal of Smart Construction

There’s a reason the market for modular homes is booming—people are catching on to their unique mix of savings, speed, and quality. Modular homes need less labor and go up faster, which often translates into lower upfront costs for you. Better yet, they appreciate in value just like site-built homes, giving you a stable and reliable investment. To see how these numbers actually play out in a budget, check out our guide on custom home builder costs.

This combination of cost savings, green benefits, and strong resale value makes modular a powerful choice. It’s simply a smarter way to build a home that works for you now and in the future.

No matter which path you choose, modular or stick-built, it's crucial to think about how your decisions will affect your property's long-term worth. It's always a good idea to explore strategies on how to add value to your home over the years. With over 21+ years of proven results, our team at SEGC is dedicated to building homes that aren't just beautiful—they’re wise, lasting investments for the families we're proud to serve.

So, Which Building Path Is Right for You?

When it comes to the modular vs. stick-built debate, the final decision really boils down to what matters most to you. There's no single "best" answer, only the answer that's best for your family's specific needs, budget, and vision for your future home.

Think of it this way: if speed, a predictable budget, and top-notch energy efficiency are at the top of your list, a modular home is an incredibly strong option. For families in the Fayetteville area who need a solid, high-quality home without a long, drawn-out construction process—maybe you're dealing with a military transfer or just need more space, fast—the streamlined factory build is tough to beat.

The Deciding Factors

Now, if your dream home is a truly unique architectural statement with complex angles and a completely custom footprint, you'll probably lean toward a stick-built home. This traditional path offers almost unlimited design freedom, letting you craft a one-of-a-kind home from the ground up, with every detail built on-site. The trade-off is usually a longer timeline and a bit more budget variability.

As a Native American-owned firm with 21+ years of proven results, our real strength isn't just in construction—it's in helping our clients find clarity. We don't have a favorite method. We listen to what you want and use our deep local experience to point you down the path that best serves your family's legacy. Our commitment is to client trust, first and foremost.

At the end of the day, this isn't just about putting up walls; it's about creating a place that truly fits your life. To dig a little deeper and get more perspective, you can explore further insights on home construction.

Our goal at SEGC is to empower you with the right information so you can make a confident choice. We build relationships first, then we build homes. If you're ready to talk about your vision, reach out to the SEGC team. Let our legacy of trust in the Fayetteville and Lumberton communities guide you home.

Let's Tackle Those Lingering Questions

Alright, we've unpacked the big differences between modular and stick-built homes. But I bet you still have a few questions buzzing around. After building homes in Fayetteville and Lumberton for over 21 years, we've pretty much heard it all. Let's clear up some of the most common head-scratchers with some actionable insights from our local experts.

Is Getting a Loan for a Modular Home a Huge Hassle?

Not at all. This is probably the biggest myth out there. Lenders treat modular and stick-built homes the same way because, well, they are the same in the eyes of the law. Once it's on a foundation, it's real estate.

You can get all the usual loans—FHA, VA, conventional mortgages, you name it. The only tiny difference is you'll likely use a construction-to-permanent loan, which pays out in stages as the work gets done. It sounds complicated, but we walk our clients through it every day to make sure it's a total non-issue.

Can a Modular Home Really Stand Up to a Hurricane?

You better believe it. Modern modular homes aren't just built to the same tough building codes as stick-built houses; they often blow right past them.

Think about it: each module has to be sturdy enough to be lifted by a crane and trucked down a highway. That means they're often built with extra bracing and structural overkill that makes them incredibly rigid and tough. As a local firm with deep roots in Lumberton and Fayetteville, we engineer every single home we build—modular or stick-built—to handle whatever North Carolina weather throws at it. Our client's safety is our top priority.

Will My Modular Home Be Worth Less When I Go to Sell It?

Nope. This one needs to be put to rest for good. A modular home's value grows (or falls) right alongside its stick-built neighbors.

When an appraiser comes to your house, they don't care how it was built. They look at location, square footage, the condition of your roof, and your killer kitchen remodel. The construction method simply isn't a factor in the final number. A quality home is a quality home, and it holds its value.

Ready to build a legacy, not just a structure? The team at South Eastern General Contractors is here to bring your vision to life with the kind of care and quality you can count on. Our Native American-owned, 8(a), and HUBZone certified firm has delivered proven results for over 21 years. Let's start the conversation about your future home: https://www.southeasterngc.com