How to Be Your Own General Contractor & Build Your Legacy

When you decide to act as your own general contractor, you're taking on a massive new role. You become solely responsible for hiring every single subcontractor, creating and managing the project schedule, controlling the budget, and making sure the finished build is up to code and meets your quality standards.

This isn't a hobby. It's a full-time job that demands intense project management skills and a surprising amount of industry knowledge.

Should You Be Your Own General Contractor?

Before you even think about breaking ground, it’s time for an honest talk with yourself. The allure of saving a chunk of money by managing your own custom build is strong, but truly understanding how to be your own general contractor requires a major reality check. This isn't a weekend project; it's a high-stakes commitment that will test your time, your bank account, and your sanity in ways you can't yet imagine.

Here at South Eastern General Contractors (SEGC), we've spent more than 21 years building lasting structures and legacies for communities from Fayetteville to Lumberton. As a local, Native American-owned, 8(a), and HUBZone certified firm, we have a deep commitment to client trust and quality. We've seen exactly what it takes to turn a set of blueprints into a beautiful, solid home, and drawing from our proven results, we want to give you a clear-eyed view of the immense demands and the essential skills you absolutely must have to pull this off.

The Real Cost of Being the Boss

Let's get right to it. The main reason people go this route is to save money, specifically the 10% to 20% fee that a professional GC would charge. And yes, those savings are possible. But they come at a steep personal price.

This role requires your full attention. You have to be ready to drop everything to solve a problem on-site, meet an inspector who just showed up, or answer an urgent call from a subcontractor. It’s a constant juggling act of dozens of moving pieces. The pressure can be incredible, and one small mistake—a failed inspection or a delayed lumber delivery—can set off a chain reaction of expensive delays and budget blowouts.

A Note from Experience: We've been called in to consult with many homeowners in the Fayetteville area who started their own projects, only to realize the sheer volume of work was more than they could handle. The savings they were counting on often evaporated, eaten up by mistakes a seasoned pro would have sidestepped. Our mission is to build legacies, not just structures, and that means doing it right the first time.

The Skills That Aren't Optional

To succeed as your own GC, you need more than just grit. You need a specific set of skills that professional builders spend years honing. Before you commit, be brutally honest about whether you have what it takes:

- Real Construction Knowledge: Do you know the correct sequence of a build? Can you spot the difference between what a foundation inspector looks for versus a framing inspector?

- Tough Negotiation & Vetting Chops: Are you comfortable negotiating contracts with subs and suppliers? Do you know exactly how to check their licenses, insurance, and references to make sure they're legitimate?

- Iron-Clad Financial Discipline: Are you prepared to track every single penny, manage a constant flow of invoices, and handle payments to keep the project afloat?

- Exceptional Problem-Solving: When your plumber is a no-show or the wrong windows get delivered, can you find a solution on the fly without panicking and letting the entire schedule fall apart?

To help you visualize the shift in duties, here's a look at how your role changes when you become your own GC.

Role Comparison: Homeowner vs. General Contractor

| Responsibility | Typical Homeowner Role | Owner as General Contractor Role |

|---|---|---|

| Budgeting | Set overall budget, secure financing. | Create a detailed line-item budget, track all costs, manage payments. |

| Scheduling | Aware of the general timeline. | Create, manage, and enforce a complex critical path schedule. |

| Hiring | Hire one general contractor. | Hire, vet, and contract 15-20+ individual subcontractors. |

| Permitting | Rely on the GC to handle all permits. | Personally apply for, manage, and schedule all necessary inspections. |

| Material Sourcing | Choose finishes like tile and paint. | Order and coordinate delivery for all structural materials. |

| Site Management | Visit the site periodically. | Be on-site daily, solve problems, ensure safety and quality. |

| Liability | GC holds primary site liability. | You assume 100% of the liability for accidents and errors. |

Seeing it laid out like this makes the scope of the job much clearer. The responsibilities multiply exponentially.

Companies like SEGC exist for a reason. As a Native American-owned, 8(a), and HUBZone certified firm, we were built to manage these complexities. Our commitment to client trust and quality is what has allowed us to thrive for over 21 years. We bring the expertise and the battle-tested systems needed to guide a project smoothly from start to finish.

Before you decide to take this journey alone, make sure you understand the full picture. A great next step is to get a deeper sense of what a general contractor really does. Knowing the role inside and out will help you weigh the dream of saving money against the very real risks of going it alone.

Getting a Grip on Your Construction Budget and Finances

If deciding to be your own general contractor is the "what," then your budget is absolutely the "how." In our 21+ years building homes and legacies across Fayetteville, Lumberton, and beyond, we’ve seen one thing derail more projects than anything else: poor financial planning. It’s the fastest way to turn a dream build into a waking nightmare.

Forget about a simple spreadsheet with a few high-level numbers. That’s not a budget; it’s a guess. To pull this off, you have to think like a seasoned project manager. This means creating a detailed, resilient budget that can handle the inevitable curveballs every construction project throws. It requires a meticulous, line-by-line approach that accounts for everything from the concrete in the foundation to the very last light fixture.

Building Your Line-Item Budget

Your first real task is to break down the entire project into its smallest possible pieces. I don't mean broad categories like "Plumbing" or "Framing." You need to get granular: "Framing labor," "Lumber costs," "Fasteners," "Exterior sheathing," and so on. A painfully detailed breakdown is your single best defense against surprise costs.

This can feel overwhelming at first. It’s why we meticulously map out every phase for our clients. Taking a look at our guide to the custom home building process can give you a solid framework for the stages you'll need to budget for.

A professional GC’s secret weapon is years of historical data and established relationships. They just know the going rates. You, on the other hand, have to pound the pavement to get accurate subcontractor quotes. Never settle for one bid. Aim for at least three for every major trade. This not only gives you a realistic price range but also helps you spot a bid that’s suspiciously low—which is almost always a red flag for shoddy work or future change orders.

A Tip from Our Experience: Around the Lumberton area, we often see owner-builders get burned by underestimating site work. Things you can't see, like unexpected soil conditions or complex drainage needs, can add thousands to a budget in a heartbeat. Always insist on a formal quote for grading and foundation work based on an actual site visit, not just a guess from your plans. This commitment to detail is how we build client trust.

The Contingency Fund: Your Non-Negotiable Safety Net

Let's be clear: no budget is perfect. Prices will change, someone will make a mistake, and you might just decide you have to have those upgraded countertops halfway through the build. This is precisely what your contingency fund is for. It isn't "extra" money; it's a critical, planned-for part of your total project cost.

We always advise our clients to build in a contingency of 15% to 20% of the total construction cost.

- For a $400,000 build, that means setting aside $60,000 to $80,000.

This fund is what saves you. It covers unforeseen issues, sudden material price hikes, or scope changes without forcing you to cut corners elsewhere or, worse, halting the project entirely. The real discipline for an owner-builder is resisting the temptation to dip into it for non-emergencies.

Tracking Expenses and Managing Cash Flow

Creating the budget is one thing; managing it in real-time is where most self-managed projects truly stumble. This is all about tracking every dollar and managing your cash flow. The construction industry is infamous for its financial pressures. In fact, statistics from 2022 showed that 20% of new construction companies fail within their first year, and that number skyrockets to nearly 50% by the five-year mark, largely due to poor cash flow management. This shows why meticulous tracking isn't just a good idea—it's a survival tactic.

Start by opening a dedicated bank account for the project. From there, use accounting software or a robust spreadsheet to log every single invoice and receipt the moment you get it. You need a crystal-clear, up-to-the-minute picture of where your money is going. This discipline is what allows you to make smart decisions on the fly and ensures you always have the cash ready to pay your trades on time—a crucial part of keeping your project moving and everyone happy.

Navigating Permits and Assembling Your A-Team

With your budget looking solid, you’re now facing two of the biggest hurdles in any custom build: wrestling with bureaucracy and hand-picking your crew. Honestly, how you handle these next steps is what separates a smooth, successful project from a chaotic mess of delays and headaches.

The first challenge is the local permitting process. This isn't just one form you fill out. It’s a whole series of applications, plan reviews, and on-site inspections designed to make sure your new home is safe and up to code. After 21+ years in this business, we at South Eastern General Contractors can navigate the permit offices in Fayetteville, Lumberton, and the surrounding areas with our eyes closed. For a first-time owner-builder, though, it can feel like trying to learn a completely new language.

Demystifying the Local Permitting Process

Your journey starts at your city or county planning and inspections office. This is ground zero. You can’t move a single scoop of dirt until your architectural plans have been officially reviewed, stamped, and a building permit is in your hand.

The exact paperwork can differ from one municipality to the next, but you should count on needing the following:

- A Completed Permit Application: The main form from your local government.

- Full Sets of Blueprints: They'll often want several copies to distribute to different departments.

- A Detailed Site Plan: This map shows your property lines, where the house will sit, and its distance from boundaries (setbacks).

- Septic or Sewer Permit: You need to show proof that you have an approved plan for wastewater.

- Lien Agent Information: In North Carolina, you’re required by law to designate a lien agent for most construction jobs.

Getting that initial permit is a huge milestone, but it's just the starting gun. From there, you're the one responsible for calling in inspections at every critical stage—foundation, framing, rough-in plumbing and electrical, and so on, all the way to the final walkthrough. If you miss scheduling an inspection or, even worse, fail one, you're looking at expensive delays that can throw your entire schedule off track.

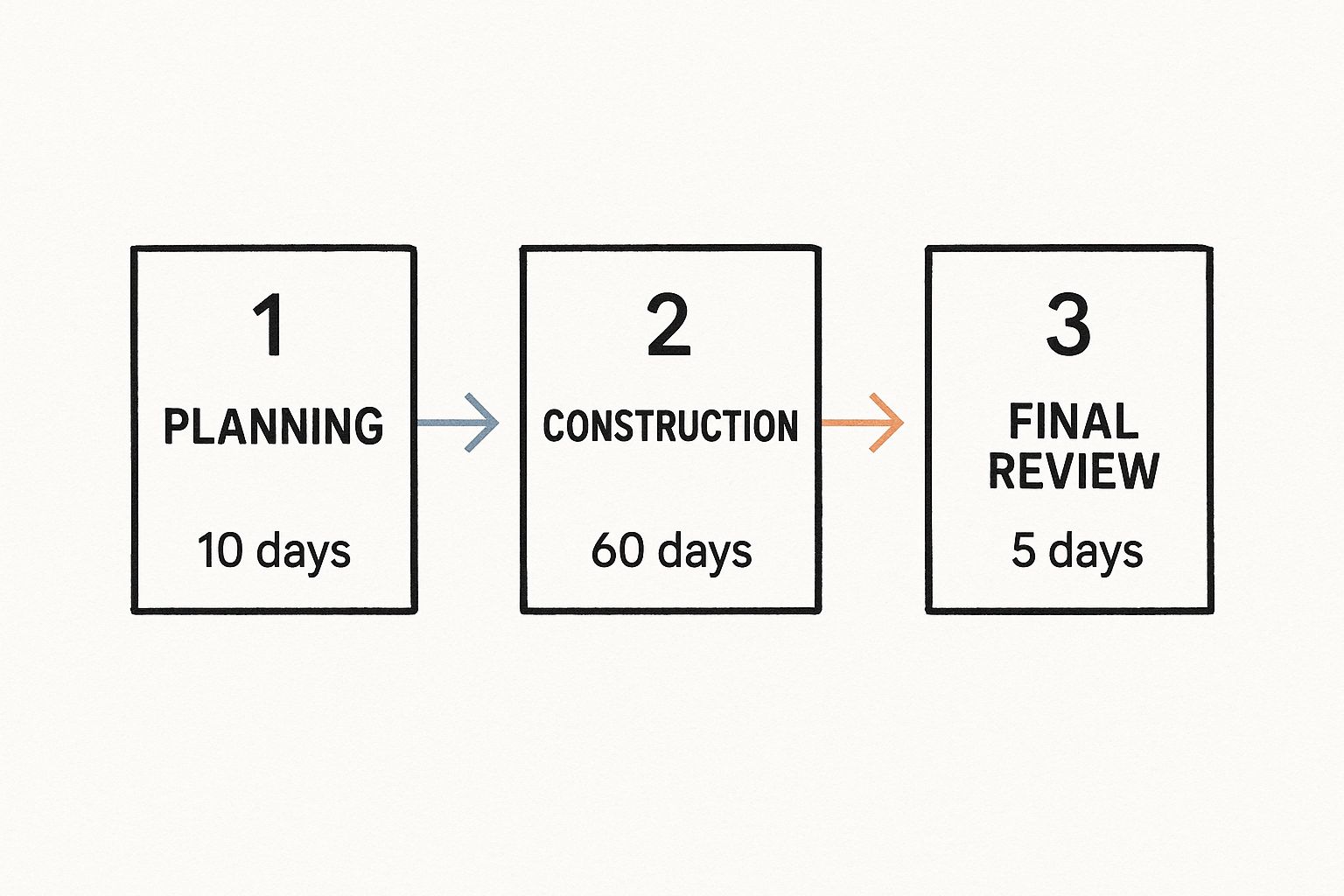

This flow chart gives you a bird's-eye view of how the major phases connect.

As you can see, the real work happens during the construction phase, but its success depends entirely on getting the planning and permitting right from the very beginning.

Assembling Your Crew of Trusted Trades

While you’re dealing with all that paperwork, you also need to be building your "A-Team" of subcontractors. I can’t stress this enough: this is probably the single most important job you'll have as your own GC. Your home will only be as good as the people who actually build it.

At SEGC, we have a deep bench of trusted trade partners we've worked with for decades. That network wasn’t built overnight. It’s the result of years of careful vetting—a system you’ll need to create for yourself. The biggest mistake you can make is just hiring the cheapest bid. In construction, a suspiciously low price is almost always a red flag for inexperience, cheap materials, or a plan to bombard you with "change orders" later on.

A Testimonial from the Field: An SEGC project manager once told me, "The relationship with your subs is everything. When a storm is rolling in and you need a roofer to show up on a Saturday, they don't come for the guy who nickel-and-dimed them. They come for the GC who respects their work, communicates clearly, and pays them on time. That's how we’ve built trust and impacted the Lumberton community for over two decades."

Your vetting process has to be rock-solid. For every single trade you hire, you must:

- Verify Their License: Go to the state licensing board's website and confirm their license is active and in good standing.

- Confirm Their Insurance: Ask for a Certificate of Insurance (COI). Make sure it shows both general liability and worker’s comp coverage. This is non-negotiable and protects you from massive financial risk.

- Check Multiple References: Don't just get a list of names. Call their last three clients and ask direct questions. Were they on time? How was the quality? Did they communicate well? Did the final bill match the quote?

- Scrutinize Their Contract: Look for any red flags. A vague scope of work, an unclear payment schedule, or no mention of a warranty are all good reasons to walk away.

This is the hard, unglamorous work that makes a project succeed. It’s what we do day-in and day-out, using our standing as a trusted Native American-owned, 8(a), and HUBZone certified firm to attract the absolute best talent. For you, it means doing the homework to build a team you can truly count on. Because when things go wrong—and they sometimes do—that team is your first and only line of defense.

The Art of Scheduling and Project Management

Think of a successful build as a tightly run orchestra. The blueprints are your musical score, the subcontractors are the musicians, and you? You’re the conductor. The schedule is what keeps everyone playing in harmony, dictating who does what and when. This is the art of construction sequencing, and it's absolutely essential to master if you want to learn how to be your own general contractor.

This sequence is everything. A plumber can’t run pipes through walls that haven't been framed. Drywallers can't hang a single sheet until the electrical and plumbing rough-ins are inspected and signed off. Every task depends on the one before it. One small delay can trigger a domino effect of expensive problems and scheduling headaches.

At South Eastern General Contractors, our local leadership team and project managers live and breathe the schedule. It's the one true source of information that keeps our large-scale projects in Fayetteville and Lumberton moving forward with proven results. Your job is to build a realistic timeline—from the first scoop of dirt to the final punch list—and manage it without losing your sanity.

Creating Your Construction Schedule

The first thing you need to build is a critical path schedule. This isn't just a to-do list; it's a map that identifies every key task and arranges them in the only order they can happen. You'll need to outline each phase, realistically estimate how long each step will take, and pinpoint all the dependencies.

Here’s a simplified look at how a typical build flows:

- Site Work & Foundation: This all starts with clearing the land, digging for the foundation, and pouring the concrete footings and slab.

- Framing: The skeleton of your home rises, including the walls, floor systems, and roof structure.

- Exterior Finishes: You make the house "weather-tight" by installing windows, exterior doors, siding, and roofing.

- Rough-in MEP: This is a huge phase where Mechanical (HVAC), Electrical, and Plumbing lines get run through the studs, floors, and ceilings.

- Insulation & Drywall: Once all those rough-ins pass inspection, the insulation goes in. Then, the drywall is hung, taped, and finished.

- Interior Finishes: Now the personality of the house emerges. Think flooring, trim, painting, and installing cabinets and countertops.

- Final MEP & Fixtures: Your trades return to install the visible parts: light fixtures, outlets, faucets, toilets, and major appliances.

- Final Grading & Landscaping: The focus shifts back outside to prepare the yard for grass and plantings before the final inspection.

This sequence is the backbone of your entire project. Get it right, and you're halfway there.

Why Project Management Software Is Non-Negotiable

A paper calendar and a notebook might feel old-school and simple, but the reality of a modern build is just too complex. You can't effectively juggle a dozen trades, track material deliveries, and document every change order on a legal pad. It's a recipe for absolute chaos.

The data is clear: for construction companies that make it past the critical five-year mark, embracing technology is a major factor in their success. A growing number of these firms depend on digital tools, with 41% using project management software specifically. For an owner-builder, this isn't a luxury—it's one of the smartest moves you can make. You can see the findings on construction company longevity for yourself.

These platforms let you see your timeline visually, assign tasks, and instantly communicate changes to your team. When a lumber delivery is delayed, you can adjust the schedule in real time and automatically notify every trade affected. It’s the difference between proactive leadership and reactive firefighting.

Running the Job Site Like a Pro

Managing the actual job site well is what separates a smooth project from a nightmare. It all comes down to communication, documentation, and a little bit of leadership. We’ve refined our own process over 21+ years in the business, and you can absolutely adapt our core principles for your build.

First, hold regular site meetings. Even a quick, 15-minute huddle once a week with the trades currently on site can prevent a world of hurt. It's your best chance to review the upcoming week, troubleshoot problems before they start, and make sure everyone is on the same page.

Second, document everything with daily photos. This is a non-negotiable for us at SEGC. Just take a quick walk-through with your smartphone at the end of each day. This creates an undeniable visual record of progress. Those photos are worth their weight in gold for settling disputes over work quality or proving something was installed correctly before it got sealed up behind drywall. For a deeper dive, our guide on how to manage construction projects effectively has more great strategies.

By combining a solid schedule with modern tools and disciplined habits on-site, you give yourself the power to lead your project with confidence. You're not just building a house; you're building a legacy.

Ensuring Quality and Passing Critical Inspections

When you’re learning how to be your own general contractor, you’ll find yourself wearing a lot of different hats. But none is more important than the role of Quality Manager. This is where the dream on paper collides with the reality of wood, concrete, and steel. You are the final set of eyes, the one person whose job is to make sure every single detail meets not only your personal standards but also the strict local building codes.

At South Eastern General Contractors, our site supervisors do daily walkthroughs on every project, whether it's a luxury custom home in Fayetteville or a complex commercial build in Lumberton. It's just part of our DNA. After more than 21+ years of proven results, we've learned a simple truth: catching a small mistake early prevents it from becoming a massive, expensive problem down the road.

You have to adopt this exact same mindset. Your most important job on-site is to inspect the work. Daily.

Adopting the Eye of an Inspector

You don't need decades of construction experience to spot common problems, but you do need to know what you’re looking for. A great general contractor develops an instinct for quality, and that comes from one thing: being present and paying attention.

Make it a non-negotiable habit to walk the site at the end of every single day. Bring a notepad, your phone for taking photos, and a very critical eye. This daily ritual is your single best defense against sloppy work.

A Lesson from the Field: We once consulted on a project in Fayetteville where an owner-builder was having a tough time with a subcontractor. The work was subpar, but the homeowner felt too intimidated to say anything. Our advice was straightforward: "Use your contract and the blueprints as your shield. It isn't personal; it's about what was agreed upon."

You can be firm without being confrontational. Something as simple as, "The plans show this wall should be plumb, but my level shows it's off by a quarter-inch. We need to fix this before we can move forward," is professional, direct, and non-negotiable.

Critical Milestone Quality Checks

Your project will have a handful of major inspection points, both for your own peace of mind and for the city or county inspector. Think of each one as a gateway to the next phase. Never let work proceed until you are 100% satisfied with what’s been done.

Here are the big ones to watch for:

- The Foundation Pour: Before the concrete trucks even think about showing up, you need to be out there. Double-check that all the formwork is secure, that the rebar is placed exactly according to the plans, and that any in-slab plumbing or electrical conduits are right where they belong.

- The Framing Walkthrough: Once the skeleton of the house is up—but before any wires or pipes are run—walk the entire thing with a good level and a tape measure. Are the walls plumb (perfectly vertical)? Are the corners square? Do the window and door openings match the specs?

- The MEP Rough-in: This is your last chance to see inside the walls before the drywall goes up. Visually trace the plumbing lines, make sure electrical boxes are securely fastened in the right spots, and check that the HVAC ducts are properly sealed and supported.

Passing Municipal Inspections the First Time

Failing an official inspection is more than just a headache. It's a costly delay that can throw your entire schedule and budget into chaos.

Inspectors are trained to spot specific code violations, but they’re also human. The overall condition of your job site says a lot. A clean, safe, and organized site sends a powerful subconscious message: professionalism and attention to detail.

Here’s how to prepare for an official inspection:

- Do a Pre-Inspection: Walk the site yourself with the inspector's checklist in mind. Find and fix any potential red flags before they ever set foot on the property.

- Ensure Safe Access: The inspector needs a clear, safe path. Get rid of debris, move tools out of the way, and remove any potential hazards.

- Have Your Paperwork Ready: Keep your permit card, stamped plans, and any relevant engineering documents in a binder, ready to go and easily accessible on-site.

Passing inspections on the first try is a hallmark of a well-run project. It's a standard we hold ourselves to at SEGC because we know that time is money. For you, it’s a critical part of keeping your project moving forward and building your legacy, one successful step at a time.

Why Proven Experience Is Your Greatest Asset

The idea of being your own general contractor is tempting. You see the potential to save a significant amount of money and have total control over your custom build. It's a rewarding path, but it's also paved with serious risks that can jeopardize not just your budget, but your sanity.

This is where the idea of "experience" stops being a buzzword and becomes your most critical asset. Bringing in a seasoned firm like South Eastern General Contractors isn't about giving up control; it's about gaining a partner who has navigated this complex process hundreds of times before.

With 21+ years of proven results, our team has seen it all. We’ve built legacies across communities like Fayetteville and Lumberton, and that experience taught us one crucial lesson: building is about more than just hammers and nails. It’s about foreseeing problems before they happen, juggling the intricate dance of a project schedule, and expertly leading a crew of specialized trades.

The Sobering Reality of Construction Risks

Let's be blunt: the construction industry is notoriously tough. If you look at construction firms started back in 2001, a staggering 83% of them were out of business within 20 years. That’s one of the highest long-term failure rates of any industry out there.

Why? It often boils down to a few key things: disorganized project tracking, weak leadership, and no real systems in place to keep things on the rails. You can read more about why so many construction companies face these challenges at busybusy.com.

These aren't just numbers on a page; they're a stark reminder of the discipline it takes to succeed as a general contractor. Enthusiasm is great, but it's no substitute for proven systems and a relentless focus on quality.

At SEGC, we don’t just build structures; we build client trust. Our Native American-owned, 8(a), and HUBZone certifications are testaments to an unwavering commitment to integrity and quality that has been our foundation for over two decades. This local leadership and commitment to our community is why we have thrived where so many others have failed.

When you bring us on board, you get a partner whose sole focus is protecting your vision and your investment. We dive into the daily grind—the scheduling conflicts, the surprise inspection issues, the constant problem-solving—so you don't have to. We take on the risks so you can enjoy the reward, knowing your legacy is being built, not just a house.

Answering Your Biggest Questions

If you're thinking about being your own general contractor, you've probably got a lot of questions running through your mind. It’s a huge undertaking. After more than 21 years building homes and creating legacies in places like Fayetteville and Lumberton, we've heard them all. Here are some straight-up answers to the most common ones we get.

How Much Can I Realistically Save?

Everyone gets drawn in by the idea of saving that 10% to 20% GC fee, and it's definitely possible. But here's the reality check: those savings are not a given. They entirely depend on you not making expensive mistakes.

A single scheduling hiccup that leaves a crew standing around, one failed inspection that pushes everything back a week, or a detail you missed in a subcontractor's quote can wipe out that potential savings in a heartbeat. You also have to factor in the cost of your own time, stress, and the learning curve that a seasoned pro has already mastered.

What Is the Single Biggest Pitfall for Owner-Builders?

Hands down, the biggest mistake we see is underestimating the time commitment. This isn't a hobby you can squeeze in on weekends or after work. Managing a custom build is a full-time job, and then some.

The people who succeed at this are the ones who can essentially clear their schedules and live at the job site. They're there every day, ready to answer questions, solve problems on the fly, and keep the momentum going. Anything less, and you're just asking for delays and chaos.

At SEGC, we've built our reputation on transparency and building client trust. The truth is, a beautiful home doesn't just happen. It's the result of constant, daily, dedicated management on the ground. That vigilance is the foundation of everything we build in the Fayetteville and Lumberton communities.

Do I Really Need to Worry About Insurance?

Yes. One hundred percent, absolutely. When you step into the role of general contractor, you take on 100% of the liability for everything and everyone on that site. That means injuries, theft, damage—it all falls on you.

You'll need to secure a solid builder's risk insurance policy for the project itself. Beyond that, you must personally confirm that every single subcontractor who sets foot on your property has their own general liability and worker's compensation insurance. Don’t just take their word for it; get the certificates. This isn't just a recommendation; it's the only thing protecting you and your largest financial investment from a potential disaster.

At South Eastern General Contractors, we get the dream of building your own home. We also have a deep respect for the challenges that come with it. Our experience, backed by our Native American-owned, 8(a), and HUBZone certifications, offers a reliable path forward. We handle the risks and the day-to-day grind so you can stay focused on the dream.

If you’re ready to create a lasting legacy without taking on all the weight yourself, let's talk. Our mission is building legacies, not just structures. Contact us today at South Eastern General Contractors to get the conversation started.