How to Reduce Construction Costs: An Expert Guide to Saving Money

The secret to reducing construction costs isn’t about cutting corners during the build—it’s about strategic, expert planning before a single shovel hits the dirt. A project that’s meticulously planned and backed by a seasoned, trustworthy team is your best defense against the budget surprises and change orders that can derail a project.

Your Blueprint for Building Smarter, Not Harder

Cost overruns are so common in construction that some studies show they impact nearly 98% of all projects. This isn't just bad luck; it’s often the result of rushed planning and a failure to establish financial certainty from the very beginning.

This guide provides an actionable roadmap to protect your investment, based on the proven processes we use every day.

For over 21 years, the team at South Eastern General Contractors (SEGC) has been turning ambitious visions into concrete reality for clients in Fayetteville, Lumberton, and across the region—without the sticker shock. We’ve built our reputation on a foundation of trust and proven results. Our unique strengths as a Native American-owned, 8(a), and HUBZone certified firm empower us to deliver exceptional value and quality.

The SEGC Philosophy on Cost Control

Our approach to cost control is a comprehensive strategy focused on long-term value and efficiency, not just short-term savings. We know from two decades of experience that real savings come from a smarter playbook.

- Intense Pre-Construction Deep Dives: We identify potential site issues, regulatory hurdles, and inefficient design elements before they can impact your budget. This proactive mindset is the cornerstone of how we build trust with every client.

- A United Design-Build Front: By bringing architects, engineers, and our construction experts together from day one, we develop smarter, more buildable plans that reduce waste and maximize the value of every dollar spent.

- Homegrown Leadership and Connections: Our deep roots in communities like Fayetteville and Lumberton mean we have an intimate understanding of the local permitting processes and strong relationships with trusted suppliers. This efficiency translates directly into savings for you.

Over our 21+ years at SEGC, we’ve learned that the most expensive part of any project is rework. By obsessing over the details upfront, we ensure we’re building a legacy, not a liability.

We're pulling back the curtain on the exact strategies we use every day to provide you with actionable, no-fluff advice to protect your investment.

Winning the Budget Battle Before You Break Ground

The biggest mistakes that sink a construction budget don’t happen with a hammer and nails; they happen during the planning phase. Rushed or incomplete planning is the number one cause of the change orders and surprise expenses that can turn a dream project into a financial burden.

After 21+ years in this business, we at SEGC can state with certainty that the most critical phase for controlling costs is pre-construction.

This phase is about building a financial fortress around your vision. It’s not about cutting corners; it’s about making smarter, more informed decisions from the start. We've seen firsthand on projects throughout Fayetteville and Lumberton how a little extra diligence upfront can save tens of thousands of dollars down the line.

Uncovering Problems Hiding in Plain Sight

Every piece of land has a story, and sometimes that story includes expensive problems lurking just beneath the surface. A thorough site analysis is your first line of defense. This goes far beyond a simple property line survey.

We’re talking about geotechnical surveys to understand soil stability and identify potential foundation issues. It's about locating utility connections and potential easements that could reshape your site plan. On a recent commercial project near Lumberton, our early site investigation revealed an unmarked drainage issue that would have flooded the new foundation. Catching it early turned a potential $50,000 catastrophe into a manageable $5,000 rerouting job. This is the kind of proactive problem-solving that defines our approach.

To get an even clearer picture, modern tools are a game-changer. Using aerial surveying UAV technology provides a highly detailed overview of the land before anyone sets foot on site, allowing for more precise planning.

Crafting a Painfully Detailed Budget

A vague budget is an invitation for costs to spiral. A real budget is a line-by-line document that accounts for everything, from major material orders to minor permit fees. This isn't an estimate; it's your financial blueprint.

A rock-solid pre-construction budget must include:

- Soft Costs: Fees for architects, engineers, permits, and insurance.

- Hard Costs: The core expenses—materials, labor, and equipment.

- Site Costs: Excavation, utility connections, and landscaping.

- Contingency Fund: This is non-negotiable. A buffer of 5-10% of the total budget must be set aside for truly unforeseen issues.

This level of detail leaves no room for assumptions. It forces critical conversations early and ensures every dollar has a purpose before it’s spent.

"At SEGC, our commitment to client trust begins here. We believe a transparent, hyper-detailed budget isn't just good business—it’s a moral obligation. It’s the foundation upon which we build relationships that last long after the project is complete."

The Power of Getting Everyone in the Room Early

One of the most effective ways to reduce construction costs is to get all key players collaborating from day one. When architects, engineers, and contractors work in silos, you get designs that are beautiful but impractical or unnecessarily expensive to build. This is where our expertise as a design-build firm makes a significant difference.

Bringing everyone to the table early creates a unified, cost-conscious team. The architect can design with specific, affordable materials in mind, while our project leads provide real-time feedback on labor costs and buildability. This collaborative approach, guided by a team that knows how to find a good contractor, is central to our process. As a Native American-owned, 8(a), and HUBZone certified firm, we don’t just put up structures—we unite stakeholders to build lasting legacies.

Using Smart Design to Engineer Major Savings

A great design does more than just look good on paper; it actively works to protect your budget. The choices made on the blueprint are among the most powerful tools you have to reduce construction costs, impacting everything from the initial build to long-term utility bills. This is where we move beyond aesthetics and into the strategy of smart savings.

We’ve spent over 21 years at SEGC helping clients in Fayetteville and Lumberton view their projects as long-term assets. A small, intelligent tweak during the design phase can create massive positive ripples through the final budget. It’s about questioning every element to ensure it adds real value, not just unnecessary cost.

Value Engineering Your Vision

One of the most powerful tools in our cost-saving arsenal is value engineering. This isn't a technical term for using cheaper materials. It's about finding smarter, more efficient ways to achieve the same—or better—results. It is a collaborative process where we analyze every component of the design to enhance performance and eliminate unnecessary expense.

For instance, simply modifying a building’s layout to align with standard material sizes—like 8-foot or 12-foot lumber—can dramatically reduce material waste and the labor hours spent on custom cuts. It’s a simple concept that produces real savings. You can learn more about what value engineering in construction is and how it can be a game-changer for your project.

Another effective strategy is to simplify the building's footprint. A complex shape with numerous corners and an intricate roofline looks impressive, but it’s a budget-killer. Each extra corner adds complexity to the foundation, framing, and roofing, driving up both material and labor costs. Streamlining the form can provide the same functional space for a fraction of the price.

Designing for Long-Term Efficiency

Your initial construction cost is just the first chapter of the financial story. A truly cost-effective design considers the building's entire lifecycle. This is where sustainable and energy-efficient practices become powerful financial tools.

Embracing these forward-thinking building practices can slash lifecycle costs by 20-30% through lower energy bills and reduced maintenance. By designing with sustainability standards in mind, we not only cut long-term operational expenses but can also lower upfront costs by minimizing waste and optimizing schedules.

Here are a few actionable ways we put this into practice:

- Harnessing Natural Light: We strategically place windows and skylights to reduce the need for artificial lighting, lowering electricity bills from day one.

- Optimizing Insulation: Investing in superior insulation and a tight building envelope means your HVAC system works more efficiently, saving you money every month.

- Sourcing Locally: Whenever possible, using materials sourced from the Fayetteville or Lumberton area reduces transportation costs and supports our local community—a core value for us as a HUBZone certified firm.

Local Project Story: On a recent commercial project in Fayetteville, our team identified an opportunity to reorient the building's main facade. This simple design change maximized southern exposure for passive solar heating in winter and allowed for an overhang to provide crucial shade in summer. That single adjustment is projected to save the client well over six figures in energy costs over the building’s lifetime.

From Blueprint to Reality

Ultimately, smart design is about foresight. It's about understanding the financial impact of every decision before a single nail is hammered. This proactive approach is the foundation of the trust we build with every client. As a Native American-owned and 8(a) certified contractor, our mission goes beyond just finishing on time and on budget. We’re here to help you build a legacy—one that’s as financially sound as it is structurally solid.

Mastering Your Materials and Procurement Game

If your project's blueprint is the brain, then materials are its heart and soul. They can also account for 50% or more of your total budget. Simply ordering materials as needed is a surefire way to see costs escalate. With over two decades of experience, we have transformed procurement from a simple expense line into a powerful tool for saving money.

It's about strategic foresight—knowing precisely when to buy, who to buy from, and what alternatives can deliver better performance for less.

Timing the Market and Buying in Bulk

Material prices fluctuate with market demand, supply chain dynamics, and even the seasons. A smart procurement strategy is about more than finding today's lowest price—it's about anticipating tomorrow's costs. By closely monitoring market trends, we can lock in prices on critical materials before a price hike, securing significant savings before work begins.

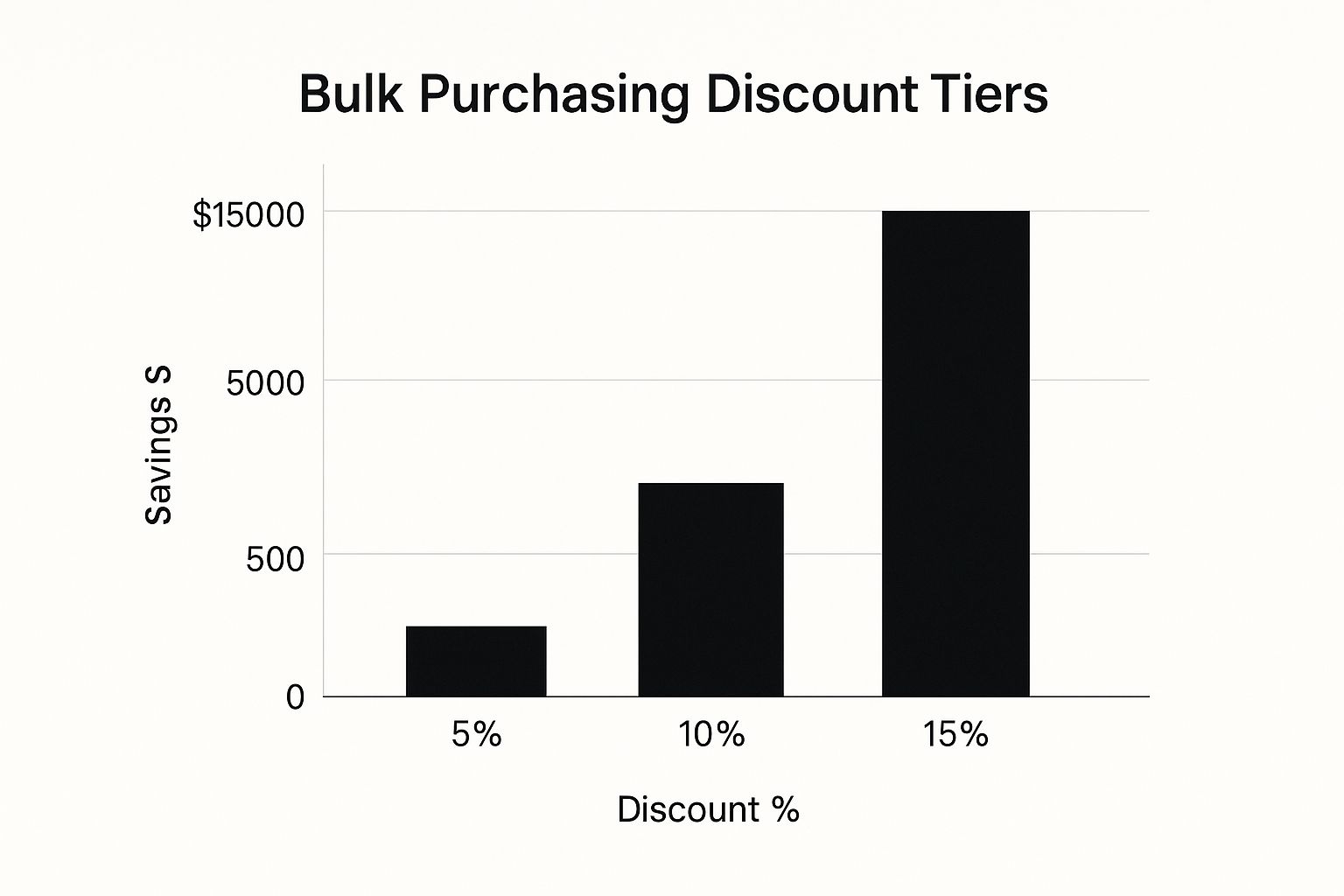

Another proven strategy is buying in bulk. With a well-defined project scope, we can confidently order larger quantities of materials like lumber, drywall, and concrete. Suppliers often offer volume discounts, and these per-unit savings accumulate into substantial value on a large project.

This chart illustrates how quickly these discounts can add up.

As you can see, shifting from small, reactive orders to strategic, high-volume buys doesn't just save a little—it compounds your savings significantly.

Why Your Local Supplier is Your Best Friend

In this business, strong relationships are more valuable than any one-time discount. Over our 21+ years, we've built rock-solid partnerships with trusted local suppliers in the Fayetteville and Lumberton areas. They are true partners who share our commitment to quality and integrity.

"Our suppliers are an extension of our team. Because they know and trust us, we get the first call about a new product, a heads-up on a price increase, or extra flexibility on a delivery schedule. That trusted relationship is invaluable, and it’s a benefit we pass directly to our clients."

This local network means we can often source top-notch materials faster and at a better price, improving supply chain efficiency by cutting logistical hurdles.

Thinking Outside the Traditional Toolbox

A smart budget doesn't mean compromising on quality. It often means being open to innovation. We are constantly evaluating alternative materials and methods that can outperform traditional options while saving you money.

Below is a quick look at how innovative thinking can impact the bottom line.

Cost Reduction Strategies Comparison

| Area of Focus | Traditional Approach | Cost-Saving Alternative | Potential Savings |

|---|---|---|---|

| Framing | Stick-built on-site with dimensional lumber. | Prefabricated wall panels or Structural Insulated Panels (SIPs). | 10-15% on labor and waste. |

| Siding | Expensive hardwood or natural stone veneer. | High-quality fiber cement or composite materials. | 20-40% on material and long-term maintenance. |

| Decking | Ipe or other exotic hardwoods. | Capped composite or PVC decking. | 15-30% upfront, plus near-zero maintenance costs. |

| Insulation | Standard fiberglass batts. | Spray foam or rigid foam boards with higher R-value. | 5-10% on materials, plus significant long-term energy savings. |

This table just scratches the surface. The key is to constantly ask the right questions:

- Exploring Smart Alternatives: Is there a composite material that offers greater durability and lower maintenance than traditional wood? Could a different insulation provide a better R-value for the same cost? We explore these questions on every project.

- Embracing Prefabrication: Off-site construction is a game-changer. Building components like wall panels or roof trusses in a controlled factory setting reduces on-site labor, avoids weather delays, and dramatically cuts material waste. It's a powerful strategy for tightening both timelines and budgets.

Our process ensures every plank, pipe, and panel is analyzed for its true value. It’s about making smart, strategic choices that bring your vision to life without breaking the bank.

Running an Efficient and Cost-Effective Job Site

A chaotic job site is a money pit. An efficient one is a profit center. After more than 21 years of leading projects in Fayetteville, Lumberton, and across the region, we've learned the biggest on-site savings come from expert management of people, processes, and schedules.

This is where leadership makes all the difference. You can have the best plans in the world, but without firm and experienced site management, a project can quickly fall behind schedule and go over budget.

An organized site is the result of meticulous planning and strong leadership. When trades are waiting on materials or are unclear on their daily goals, the clock is ticking and your budget is shrinking. Our site supervisors are masters of logistics, ensuring every team has what they need, exactly when they need it, to keep the project moving forward efficiently.

Tackling the Skilled Labor Crunch with Smart Management

The skilled labor shortage is a major challenge in construction, impacting timelines and inflating costs. The solution isn't just having more people on site; it's having the right people doing the right tasks at the right time to avoid downtime and costly rework.

This is where proactive labor management becomes your secret weapon.

Proper labor management is critical. Studies show that poor coordination can add 10-20% to project budgets. As a leader in the Fayetteville and Lumberton communities, we focus on smart workforce management and leveraging digital tools to track crews and materials in real-time, which slashes waste and boosts efficiency.

At SEGC, we view our skilled trade partners as an extension of our family. Our commitment as a Native American-owned and HUBZone-certified firm is to invest in local talent from our communities. We provide them with clear direction and a safe environment where they can do their best work. It’s simple: when people feel respected, they build better.

To further enhance efficiency, many firms are adopting virtual reality training solutions to improve skills and site safety. A well-trained team is an efficient, safe, and cost-effective team.

Safety Isn't an Expense—It's an Investment

Some contractors view safety programs as just another cost. We see safety as a cornerstone of an efficient and profitable project. A safe job site is a productive job site. Period.

Every accident, no matter how small, triggers a chain reaction of delays, paperwork, and potential work stoppages that can derail a schedule.

Here’s how a top-tier safety program puts money back in your pocket:

- Lower Insurance Premiums: Our proven safety record directly translates to lower workers' compensation and liability insurance costs.

- Prevention of Costly Delays: A single serious incident can shut a site down for days. Proactive safety prevents these massive, budget-killing delays.

- Improved Morale and Productivity: When a crew feels safe and valued, they are more focused and productive. A culture of safety is a culture of high performance.

Our investment in safety is a core part of the trust our clients place in us and reflects our commitment to building legacies, not just structures.

Using Technology for Flawless On-Site Coordination

Running a modern construction site with a clipboard is a recipe for inefficiency. We rely on project management technology to ensure communication is clear and every trade moves in harmony. This digital backbone is essential, whether we're building in Fayetteville or a remote government facility.

This technology allows for real-time updates from the field, so subcontractors know exactly when the site is ready for them. This eliminates the "hurry up and wait" syndrome that kills productivity. The right partner will have these systems dialed in. Our guide on how to choose a general contractor can help you identify a team with the right tools and expertise.

Ultimately, running a cost-effective site is about identifying small problems before they become budget disasters. It’s about relentless schedule optimization, meticulous material management, and fostering a culture where every person is committed to efficiency. This is the hands-on, expert-led approach that has defined our work for over two decades.

Answering Your Top Construction Cost Questions

After more than 21 years in this business, we've heard every question imaginable about construction budgets. It’s what keeps clients up at night, and it’s where a good contractor proves their worth. Trust is built on straight answers, so let’s address the biggest money questions we hear from clients in Fayetteville, Lumberton, and across the region.

These answers are forged from decades of hands-on problem-solving—the practical wisdom that defines our work as a Native American-owned, 8(a), and HUBZone certified firm.

What Is the Biggest Mistake That Blows Up a Construction Budget?

Hands down, the number one budget-killer is an incomplete or vague project scope from the start.

When the plan is not fully detailed, you are inviting a series of expensive change orders later in the process. Each change doesn't just add material and labor costs; it disrupts the entire schedule, and delays are always expensive.

This is why we are meticulous about the pre-construction phase at SEGC. We gather our clients, architects, and engineers and ensure every detail is finalized before breaking ground.

It’s the timeless "measure twice, cut once" philosophy. Protecting your investment isn’t just about watching pennies; it’s about having a rock-solid plan from day one. That’s how you build a lasting legacy, not a financial headache.

How Can I Save Money on Materials Without Using Cheap Stuff?

This is a great question that gets to the heart of building smart. The goal is never to be cheap; it’s to achieve exceptional value for every dollar. Our secret weapon here is value engineering.

Value engineering isn't about swapping quality materials for inferior ones. It's about finding clever, often superior, alternatives that perform the same function for less. For example, instead of traditional wood siding that requires constant maintenance, we might suggest a high-performance composite that looks fantastic, lasts longer, and is virtually maintenance-free. You save money upfront and for decades to come.

The other key is strategic procurement—knowing what to buy and when to buy it.

- Market Timing: We monitor markets to time our major material purchases, avoiding seasonal price hikes on commodities like lumber or steel.

- Supplier Relationships: With our deep roots in communities like Fayetteville and Lumberton, we’ve built lasting relationships. Our local suppliers know us, and we can often source top-tier materials at better prices.

It’s all about finding the optimal balance of quality, cost, and longevity. That is our commitment to our clients.

Is It Cheaper to Renovate an Old Building or Just Build New?

This is the classic "it depends" question. Anyone who gives you a quick answer without a thorough assessment is guessing. A major renovation might seem cheaper on paper, but it can quickly become a money pit once you uncover hidden problems.

Here’s what can turn a renovation into a budget nightmare:

- Hazardous Materials: Discovering asbestos or lead paint requires expensive, specialized abatement work that brings the project to a halt.

- Hidden Structural Damage: Finding termite damage, a crumbling foundation, or widespread rot that wasn't in the original plan can destroy a budget.

- Major Code Compliance Issues: Bringing outdated electrical or plumbing systems up to modern code can sometimes cost as much as installing a new system from scratch.

A new build, conversely, offers cost certainty. You know what you're getting from day one, with no surprises hiding in the walls.

The only way to know for sure is with a professional feasibility study. The SEGC team can perform a deep analysis of an existing structure and provide a clear, data-driven comparison of both options, allowing you to confidently decide which path is the smarter investment.

At South Eastern General Contractors, our mission is to build more than just structures. We build trust, relationships, and legacies that last. If you’re ready to partner with a team that puts your goals and your budget first, let’s talk. Contact us today to discuss your vision.