Modular vs Stick Built Homes: An Expert Guide to Building Your Legacy

So, you're ready to build a home. One of the very first, and biggest, decisions you'll face is how it gets built. The classic showdown is modular vs. stick-built construction. At its heart, the difference is pretty straightforward: modular homes are built in climate-controlled factory sections and then assembled on your land, while stick-built homes are built from the ground up, piece by piece, right on your property.

This one difference creates a ripple effect, touching everything from your budget and timeline to the final look and feel of your home. Modular often gets you in the door faster and with fewer surprise costs, whereas stick-built offers a blank canvas for your wildest design dreams. As expert builders committed to educating our clients, we're here to help you understand which path best suits your vision.

Making The Big Call: Modular Or Stick-Built?

Choosing the right way to build your home is about more than just lumber and nails; it's about building your legacy. With over 21+ years of proven results building dream homes for families in communities like Fayetteville and Lumberton, we've seen it all. Here at South Eastern General Contractors (SEGC), our reputation as a trusted, Native American-owned, 8(a), and HUBZone certified firm is built on two things: client trust and unwavering quality. We're here to give you the straight scoop so you can make the best choice with confidence.

There’s no single "best" answer. The right path is the one that aligns with your family's priorities, budget, and vision. You'll hear plenty of myths about both methods, but our experience shows that either one can result in a stunning, rock-solid home when you have the right local leadership on the job. The trick is to understand the trade-offs and choose a partner dedicated to your success.

The Core Differences At A Glance

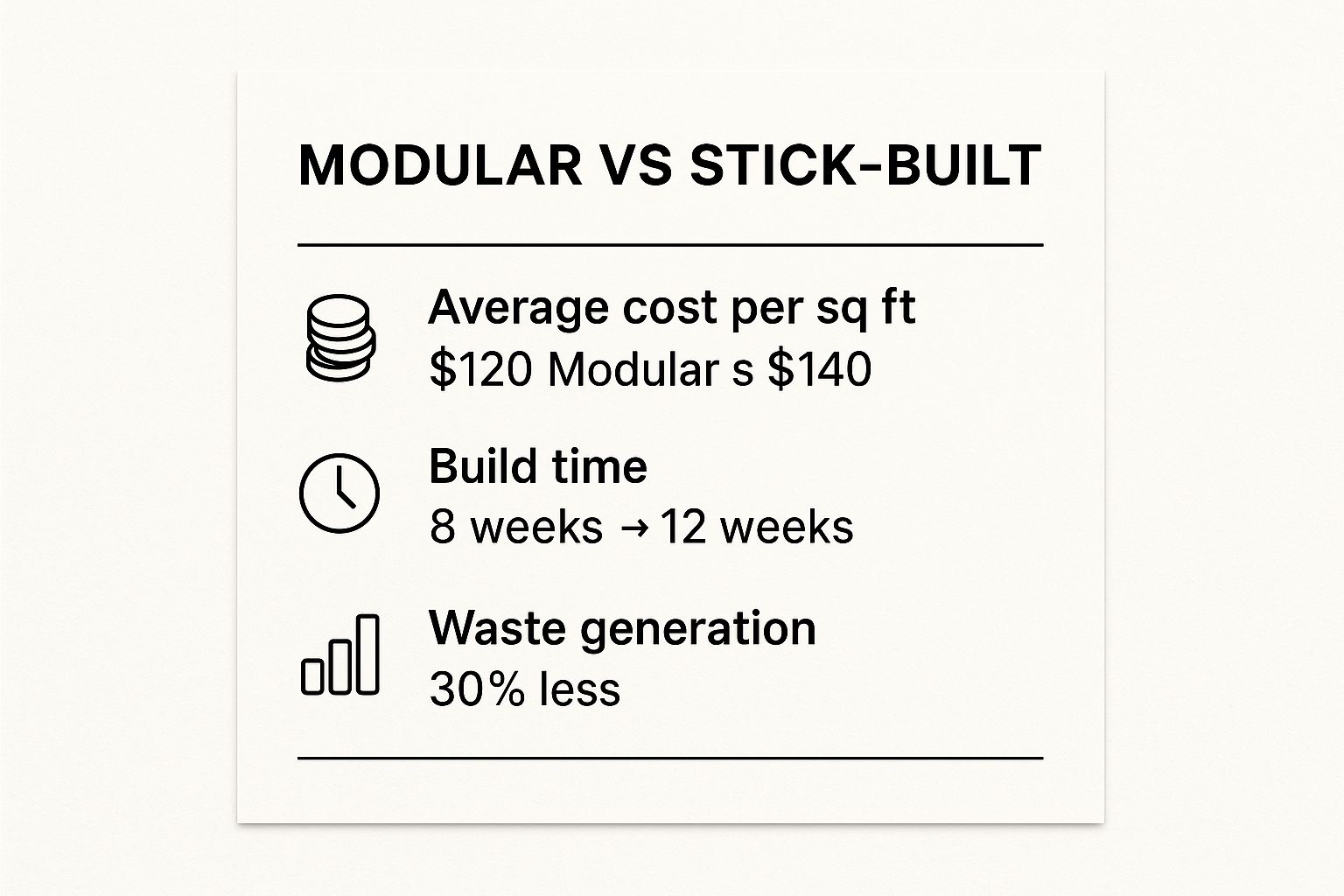

To help you see past the sales pitches, this chart breaks down the key stats comparing the two approaches.

As you can see, the factory setting gives modular construction some serious legs up in speed and cost control. Building indoors means no rain delays, and the streamlined process often translates to a more predictable bottom line. It's a huge reason why clients looking for a smooth, predictable build are drawn to modular.

To make things even clearer, let's put the two head-to-head in a simple table.

Modular vs Stick Built A Quick Comparison

Here's a quick rundown of what sets these two construction styles apart.

| Key Factor | Modular Home | Stick-Built Home |

|---|---|---|

| Build Process | Sections are built in a factory and assembled on-site. | Built entirely on-site from the ground up, piece by piece. |

| Timeline | Faster; factory work and site prep happen at the same time. | Longer; sequential process is more prone to weather delays. |

| Cost | Often more predictable with fewer budget overruns. | Can have higher labor costs and potential for surprise expenses. |

| Customization | Highly customizable within factory design parameters. | Nearly unlimited design freedom for unique or complex plans. |

At the end of the day, no matter which route you take, the final quality of your home comes down to the person holding the hammer—your builder. To make sure you've got a true pro in your corner, take a look at our guide on how to find a good contractor.

How Construction Timelines Really Compare

Let's be honest, once you've decided to build a new home, the wait can be agonizing. You just want to get your keys and start your new life. In the great modular vs. stick-built debate, the timeline is often where one method pulls way ahead of the other.

The secret weapon for modular construction is parallel processing. Think of it like a perfectly coordinated mission. While our SEGC team is on your property in Fayetteville grading the land, pouring the foundation, and getting utilities ready, your home's modules are being built at the same time in a factory. This simple overlap is a game-changer, often trimming months off the entire project.

The Domino Effect of Delays

Now, picture a traditional stick-built project. Everything happens one step at a time, in a long, sequential line. We can't even think about framing until the foundation has fully cured. The roof has to be on before we can start running the electrical wires. It’s a classic domino effect.

Here in North Carolina, we all know the weather has a mind of its own. A solid week of rain in Lumberton can bring an entire site to a standstill, pushing back not just the carpenters, but the electricians, plumbers, and painters that follow. With our 21+ years of proven results building in NC, we’ve seen it happen time and time again. Those delays don't just mess with your move-in date; they can rack up extra costs for things like temporary housing or extending your construction loan.

As a trusted, Native American-owned firm, we're all about straight talk. While we love the unmatched customization of stick-building, its timeline is at the mercy of Mother Nature. That can add a layer of stress and expense we want our clients to be aware of, which is why transparent communication from a local leader is so critical.

Modular building neatly sidesteps most of these headaches. Since a whopping 80-90% of the house is constructed indoors, the schedule is far more reliable. The data backs this up; modular homes are consistently finished faster than their site-built counterparts. You can learn more about how modular construction can address housing needs from the Urban Institute.

From Factory Floor to Your Front Door

The big day is really something to see. Once the modules are finished, they’re trucked to your property. A crane then lifts and sets them into place, and in just a few hours—often in a single day—you have a house!

Of course, there's still work to do on-site. Our expert crew must expertly seam the modules together, hook up all the utilities, and build out exterior features like porches, decks, or a garage. But this final phase is a sprint compared to the marathon of a full stick-built project. This efficiency gives you a predictable timeline you can actually plan your life around as you get ready to build your family’s legacy.

Let's Talk Turkey: Breaking Down the Real Cost of Building

Let's be honest, when you're deciding between a modular and a stick-built home, money is usually the first thing on your mind. But looking at the initial quote is like judging a book by its cover—it doesn't tell the whole story. The real cost is hidden in the details: think material waste, labor hours, and those budget surprises that pop up when you least expect them. This is where modular and stick-built can be night and day.

A stick-built home is a one-of-a-kind masterpiece, built from the ground up, right on your land. That's its magic. But every board cut and nail hammered on-site means you’re paying for a highly customized process. All that freedom is fantastic, but it can also leave the door wide open for unexpected expenses and a bigger pile of leftover materials than you'd like.

Modular construction flips the script by taking the build indoors. By ordering materials in massive quantities, factories get a much better price, and those savings get passed on to you. Plus, building with precision machinery in a controlled setting means way less waste. You’re not footing the bill for a pile of lumber that got rained on or mis-cut and ended up in a dumpster.

The Awesome Power of a Predictable Budget

Nothing torpedoes a home-building budget faster than a surprise expense. With a traditional stick-built project, a week of bad weather in Lumberton doesn't just mean delays; it can mean damaged materials that need to be replaced on your dime. Those little hits add up.

Modular building pretty much sidesteps these headaches. Since the bulk of the work happens indoors, your budget is far more locked-in and secure. That kind of financial predictability is a huge part of the client trust we've built at SEGC. As a firm with 8(a) and HUBZone certifications, we've refined our process to deliver outstanding value and crystal-clear financials, no matter which construction method you choose.

Our Promise: For over 21+ years, we’ve been focused on building legacies, not just structures. That means giving our clients in communities like Fayetteville and Lumberton an honest, transparent financial roadmap from the very beginning. We want you to make a smart investment for your family's future, with no regrets.

This isn't just a sales pitch; the numbers back it up. A deep dive by McKinsey shows that modular techniques can slash project timelines by a massive 20% to 50% and reduce overall costs by up to 20%. Where do those savings come from? Think super-efficient factory processes, minimal waste, and a much faster on-site assembly that requires less labor.

Looking Past the Initial Quote

At the end of the day, the total cost of your home is a lot more than the builder's initial bid. It's the financing, the potential overruns, and even the value of your own time and sanity. A stick-built home can give you anything you can dream up, but you’ll need a budget with some serious wiggle room to navigate that path comfortably. Modular, on the other hand, offers a more predictable, fixed-cost investment from the get-go.

To help you get a firm grip on your finances, we've put together a guide that explains the custom home builder cost in detail. Truly understanding these numbers is the first step toward building a home that fits your dreams and your wallet.

Let's Talk About What Really Matters: Quality and Durability

There’s a stubborn myth floating around that anything built in a factory must be a step down in quality. Let's put that idea to rest right now, because when you’re weighing modular vs stick built homes, durability is a huge piece of the puzzle. The truth? Quality isn’t about where a home is built. It’s about who builds it and the commitment to excellence they bring to every project.

Here's a fact that often surprises our clients here in Fayetteville: modular homes can actually be tougher and more structurally sound. Just think about it for a second. Each section, or module, has to be built strong enough to survive a road trip on a truck and then be lifted into place by a massive crane. That journey requires a frame that can handle incredible stress, often meaning it’s built with more structural reinforcement than a typical site-built home ever gets.

The Quality Control Showdown

One of the most glaring differences in quality boils down to one thing: the environment. A stick-built home is completely at the mercy of the weather during construction. Rain, snow, blistering sun, and humidity can all take their toll on raw materials like lumber and drywall before they're even sealed up.

Now, picture a modular home. It’s assembled entirely inside a climate-controlled factory. This completely protects every board, pipe, and wire from weather damage. No warping, no moisture, no surprises. This factory setting also allows for a level of quality control that’s just plain difficult to match on an open job site. Instead of waiting for an inspector, modular construction gets continuous, multi-stage checks right on the assembly line, leading to a level of precision and consistency that's hard to beat.

"At the end of the day, both modular and stick-built homes have to meet the exact same local and state building codes. But for us, that's just the starting line. With over 21+ years of proven results, our job is to go beyond the code. We’re not just putting up houses; we’re building legacies for families in communities like Lumberton. That commitment to quality is our foundation, period."

— An SEGC Project Manager

Ultimately, it doesn't matter whether we're crafting a custom stick-built estate or assembling a high-performance modular home—our promise to you is exactly the same. As a Native American-owned, 8(a), and HUBZone certified firm, our reputation is built on client trust and excellence. We ensure every home we build, including those we’ve proudly completed for our neighbors in the Fayetteville and Lumberton communities, shines with high-quality finishes and rock-solid construction. We're building a legacy of quality, no matter the method.

Finding Your Perfect Fit in Design Flexibility

Let's tackle one of the biggest myths out there: the idea that modular homes are just boring, cookie-cutter boxes. For years, that stereotype stuck, but the reality of modern modular construction couldn't be further from the truth. It's a whole new ballgame.

Today's modular homes offer a fantastic range of design flexibility, with massive catalogs of customizable floor plans, high-end finishes, and genuinely cool architectural styles. You get to pick your layouts, window styles, siding, and all the interior details that make a house feel like your home. That said, we're always straight with our clients—if you have a truly unique vision or a tricky piece of land, the boundless freedom of a traditional stick-built home is probably the way to go.

Customization: The Blank Canvas vs. The Smart System

A stick-built home is the ultimate blank canvas. Seriously. If you can dream it up, it can be built on-site. We're talking dramatic vaulted ceilings, intricate rooflines, or a one-of-a-kind floor plan designed to perfectly frame a view. This near-limitless potential for personalization is precisely why so many people are drawn to the traditional building process.

Modular design is more like working with a sophisticated set of building blocks. While there are structural parameters, the customization within that system is impressive. You can shift interior walls, choose from a wide array of premium materials, and add site-built elements like garages, porches, or unique decks to create a home that is anything but standard issue.

Local Project Story: We recently worked with a family in Lumberton who found a modular floor plan they loved, but had their hearts set on a very specific master suite. Our team reconfigured the interior layout within the module's existing footprint, and then our on-site crew built them a beautiful custom back deck. They got the personalized retreat they dreamed of with the speed and controlled cost of modular. It’s all about finding that sweet spot through expert guidance.

So, how do you know which path is right for your vision? Here’s a table to lay it all out.

Design Freedom: Modular vs. Stick-Built

| Design Element | Modular Homes | Stick-Built Homes |

|---|---|---|

| Floor Plan | Highly customizable within set module dimensions. | Truly limitless; design from a completely blank slate. |

| Exterior Style | Wide variety of styles, siding, and roofing options. | Unrestricted. Any architectural style is possible. |

| Ceiling Height | Typically limited to 8 or 9 feet due to transport. | No restrictions; vaulted, cathedral, or custom heights. |

| Unique Shapes | Complex shapes are challenging; prefers rectilinear forms. | Easily accommodates curves, odd angles, and complex layouts. |

| Finishes/Fixtures | Extensive catalog of premium options available. | Infinite selection from any supplier. |

Ultimately, the choice comes down to what you value most. A stick-built home is for the dreamer with a one-of-a-kind design, while a modular home is for the pragmatist who wants a beautiful, customized home without starting entirely from scratch. No matter which road you take, turning that vision into a reality hinges on a strong partnership with your builder. Our SEGC team, a trusted Native American-owned firm with over 21+ years of experience, has guided countless families through this exact journey. We’re here to help you understand every single option in the custom home building process so you can build a legacy, not just a house.

The Future Of Home Building In North Carolina

Deciding between a modular and a stick-built home feels like a personal choice, but it’s actually much bigger than that. It ties directly into the future of our towns and cities across North Carolina. We're all feeling the pinch from skilled labor shortages and the desperate need for more high-quality, affordable homes. Suddenly, your building project becomes part of a much larger conversation.

As a Native American-owned company with local leadership, we're not just building houses in Fayetteville and Lumberton; we're building a future. With over 21+ years under our belts, we've always seen our work as a commitment to the long-term strength of our communities. For us, innovation isn't a buzzword—it's a responsibility. Modern methods, especially modular construction, give us a genuine way to tackle these housing challenges head-on, building better and faster for the families we serve.

A Growing Role For Modern Methods

You’d think factory-built homes would be everywhere by now, but the reality is surprising. Modular and other off-site builds accounted for a mere 2% of all new single-family homes in the U.S. in 2021. If you're curious, you can discover more about housing trends from the National Association of Home Builders. What this number really tells us is there’s a massive opportunity for forward-thinking local builders to lead the charge.

Being a true partner to our community means grabbing these opportunities. As an 8(a) and HUBZone certified contractor, we're in a prime position to help our region benefit from smarter, more efficient ways of building.

At South Eastern General Contractors, we believe building legacies means looking ahead. It means using every tool and technique available to create strong foundations—not just for homes, but for the future of the places we live, work, and raise our families.

When you pick a builder who’s invested in progress, you’re doing more than just putting up four walls. You’re casting a vote for a more sustainable and resilient future for your entire neighborhood. It’s about seeing how one project, your project, can be part of a positive ripple effect across North Carolina.

Got Questions? We’ve Got Answers.

Building a new home is a huge undertaking, and naturally, you’re going to have questions. After 21+ years in this business, helping families from Fayetteville to Lumberton, we’ve pretty much heard them all. As local experts committed to client trust, we believe in providing clear, actionable insights to empower you.

How Does The Financing Work? Is It Complicated?

This is a big one for most people. Financing a stick-built home is what most folks are familiar with: you get a single construction-to-permanent loan. It starts as a construction loan and, once we hand you the keys, it automatically rolls into a standard mortgage. Simple enough.

For a modular home, the process is almost identical. The main twist is that some lenders might release payments to the factory as your home's modules are completed, rather than just at on-site milestones. It sounds more complex than it is, and honestly, it’s a non-issue for experienced lenders.

As a long-standing, Native American-owned company with deep roots in the community, we have great relationships with local banks and credit unions who get it. They know both processes inside and out, and we'll connect you with the right people to make sure your financing is smooth sailing, whichever route you choose.

What About Resale Value? Is a Modular Home a Good Investment?

Absolutely, and it’s a myth we’re happy to bust. A modern modular home appreciates in value right alongside a stick-built one. Why? Because it’s built to the exact same strict North Carolina building codes, appraised using the same criteria, and often, it's even more structurally sound thanks to the precision of factory construction.

The old-school stigma is thankfully dying out. We're in the business of building legacies, not just structures. A high-quality, well-maintained home is always going to be a fantastic asset, and our obsession with quality ensures your investment is solid, modular or not. This is a core part of our commitment to client trust.

What’s Involved in Prepping the Land?

Getting your property ready is a critical first step, and the process is nearly the same for both building methods. We handle all of it with precision. This includes:

- Clearing and Grading: We shape the land to create a perfectly level and stable pad for your home.

- Pouring the Foundation: Whether it’s a concrete slab, a crawl space, or a full basement, this is the literal groundwork for your future.

- Running Utilities: We bring in the essentials—water, sewer, and power—right to your build site.

Here’s the game-changer in the modular vs stick built debate: with a modular build, we do all of this site prep at the same time your home is being constructed off-site. This parallel workflow is what shaves weeks, sometimes months, off the total project timeline, delivering your home faster and more efficiently.

Ready to build a legacy that lasts for generations? The team at South Eastern General Contractors is here to walk you through every step and answer every last question. Our 8(a) and HUBZone certifications are a testament to our standards, but our real pride comes from our commitment to client trust and quality. Let's start the conversation about building your future in North Carolina.