Stick Built Homes vs Modular Homes: A North Carolina Builder’s Guide

When you get down to it, the difference between a stick-built home and a modular home is pretty simple. Stick-built homes are built the old-fashioned way, piece by piece, right there on your land. Modular homes are built in large sections (called modules) inside a factory, then trucked to your property and pieced together. The real question is, what matters more to you: total creative freedom (stick-built) or getting it done fast and on budget (modular)?

Choosing Your Foundation: The Home Building Dilemma

Building a home in North Carolina isn't just about hammering nails and raising walls; it's about setting down roots and creating a legacy for your family. This guide is here to cut through the noise and give you a straight-up, honest look at stick-built versus modular construction from a team that builds both.

As a Native American-owned, 8(a), and HUBZone certified builder, we’ve been helping families in the Fayetteville and Lumberton communities make this exact choice for over 21+ years. We've seen it all. Our mission is to give you the real-world knowledge you need to pick the right path for your vision, your wallet, and your schedule, so you end up with a place you’re truly proud to call home.

Key Differences at a Glance

Before we get into the nitty-gritty, let's start with a bird's-eye view. Getting these core differences straight is the first step to feeling confident in your decision.

| Feature | Stick-Built Homes | Modular Homes |

|---|---|---|

| Construction Location | Entirely on your property, open to sun, rain, and snow. | Built inside a climate-controlled factory, then assembled on-site. |

| Customization Level | The sky's the limit. Perfect for truly unique or complex designs. | Lots of options, but you're working within factory and transport limits. |

| Build Timeline | Longer, typically 5-6+ months, and at the mercy of the weather. | Much faster, often 3-4 months, because site work and building happen at the same time. |

| Quality Control | Depends heavily on the skills of your on-site crew and contractor. | Consistent, with factory inspections at every single step. |

| Initial Cost | Usually a higher price per square foot because of all the on-site labor. | Often lower per square foot thanks to factory efficiency and bulk material buys. |

At South Eastern General Contractors, we've always said the best way to build is the way that best serves our client. We don't just put up buildings; we build relationships by steering you toward the right solution, whether it's a completely custom stick-built home or a smartly designed modular one.

After years of building around Fayetteville and Lumberton, we can tell you there’s no single "best" choice. It all boils down to what you value most.

- Timeline: Are you in a hurry to get the keys?

- Budget: How important is it that the final price tag doesn't change?

- Design: Have you been dreaming of a one-of-a-kind home?

- Location: Is your property on a steep hill or hard to access?

Actionable Insight: Before falling in love with a floor plan, take a hard look at your timeline and budget. If certainty and speed are your top priorities, start exploring modular options first. If a unique, non-negotiable design is your goal, focus your energy on finding the right custom stick-builder.

You can learn more about our process for building custom homes that are built to last.

The Art of On-Site vs. The Science of Off-Site

To really get to the heart of the stick-built vs. modular home debate, you need to understand their completely different philosophies. One is a timeless art form, the other a modern science. Both have a unique way of creating your family’s legacy here in North Carolina.

Stick-built construction is the classic method you see everywhere. It's the art of building a home piece by piece—or "stick by stick"—right on its final foundation. This approach is all about hands-on craftsmanship, with builders bringing your vision to life in the open air.

The biggest draw? Almost unlimited customization. Seriously, if you can dream it up, a talented builder can make it happen on-site. This makes stick-built the undisputed champion for one-of-a-kind architectural marvels, tricky layouts, and homes that need to perfectly hug the challenging landscapes we often find around Fayetteville.

The Precision of Factory Production

On the flip side, you have the science of modular construction. Instead of being built outside, your home is put together in sections, or modules, inside a climate-controlled factory. This whole process is built on precision, efficiency, and some seriously strict quality control.

Each module is assembled to exact specs, safe from weather delays, and inspected at every single step. After all that, they’re securely transported to your land. Once there, our team expertly cranes the modules onto the foundation and joins them together seamlessly. The result is a massive reduction in construction time and wasted materials.

While customization is more structured than with a stick-built home, don't think you're stuck with a cookie-cutter box. Modern modular designs offer a huge range of high-end finishes and flexible floor plans. The primary difference in the stick-built vs modular home process really just comes down to where most of the work gets done.

If you want to dive deeper into how these methods stack up, check out our detailed analysis of modular vs stick-built construction.

As a Native American-owned firm with 8(a) and HUBZone certifications, we’ve learned that the "best" method is the one that aligns with a client’s vision and reality. The art of a stick-built home in Lumberton can be just as powerful as the science behind a modular build in Fayetteville.

Even with the incredible efficiency of modular building, traditional on-site construction is still king. Stick-built homes make up roughly 97 percent of new single-family home production in the U.S. Factory-built housing, which includes modular, accounts for about 3 percent. You can read more about the trends in factory-built housing to see the market breakdown. This gap shows just how much people still value bespoke, on-site craftsmanship.

Comparing Real World Costs and Timelines

Alright, let's get down to brass tacks. Beyond the blueprints and building philosophies, what really matters for most families in North Carolina? Your budget and your move-in date. This is where the differences between stick-built and modular homes really come into sharp focus, and where the right choice for your project becomes clear.

Modular homes often win the race when it comes to speed and predictable pricing. It all comes down to factory efficiency—they buy materials in bulk, which cuts down costs, and they build indoors, so a rainy week won't derail your entire schedule. For our clients in Fayetteville and Lumberton who are on a tight timeline, that kind of reliability is a game-changer.

On the flip side, traditional stick-built homes offer a level of flexibility you just can't get anywhere else. Want to move a wall or change a window on the fly? You can do that. But that freedom can also stretch your timeline and your budget as you make those tweaks along the way.

The Breakdown on Budgets

The money conversation is always more detailed than just a simple price-per-square-foot figure. With a modular home, the price you’re quoted upfront is usually very close to what you'll actually pay. Why? Because all the big decisions are locked in before the first wall panel is even assembled, which means fewer surprise costs ambushing you halfway through the project.

Stick-built home costs are a bit more fluid. The initial estimate is a great starting point, but things like unexpected soil conditions, a sudden jump in lumber prices, or mid-build design changes can cause that number to creep up. Drawing on our 21+ years of project management experience, we’ve become experts at crafting incredibly detailed and transparent budgets to keep those surprises to an absolute minimum.

Actionable Insight: When comparing quotes, don't just look at the bottom line. Ask a potential stick-builder for a detailed breakdown of their cost-overrun contingency plan. For a modular builder, ask for a clear list of what is not included in the factory price, such as foundation work, utility hookups, and landscaping. This gives you a true apples-to-apples comparison.

Navigating Construction Timelines

Time is the one resource you can never get back, making the construction schedule a massive piece of the puzzle. The efficiency of modular building is truly impressive. While our SEGC crew is on your land in Fayetteville preparing the foundation, your home's modules are already being built in a factory at the same time. It’s a parallel process that slashes the overall project duration.

Stick-built construction is, by its very nature, a linear process—you can't frame the walls until the foundation is poured and cured. This step-by-step approach, combined with the potential for weather delays or subcontractor scheduling conflicts, naturally means a longer wait time.

A key takeaway from our decades of building in North Carolina is that a predictable timeline is just as valuable as a predictable budget. For many families, knowing exactly when they can move in is priceless, and that's where modular often shines.

The latest numbers back this up. A 2023 analysis found that modular homes were finished in a little over eight months after the permit was issued—that's nearly two months faster than similar stick-built homes. This gap has been widening since 2019, showing just how much more efficient off-site construction is becoming. You can dig into more of the data on modular construction speed and affordability yourself.

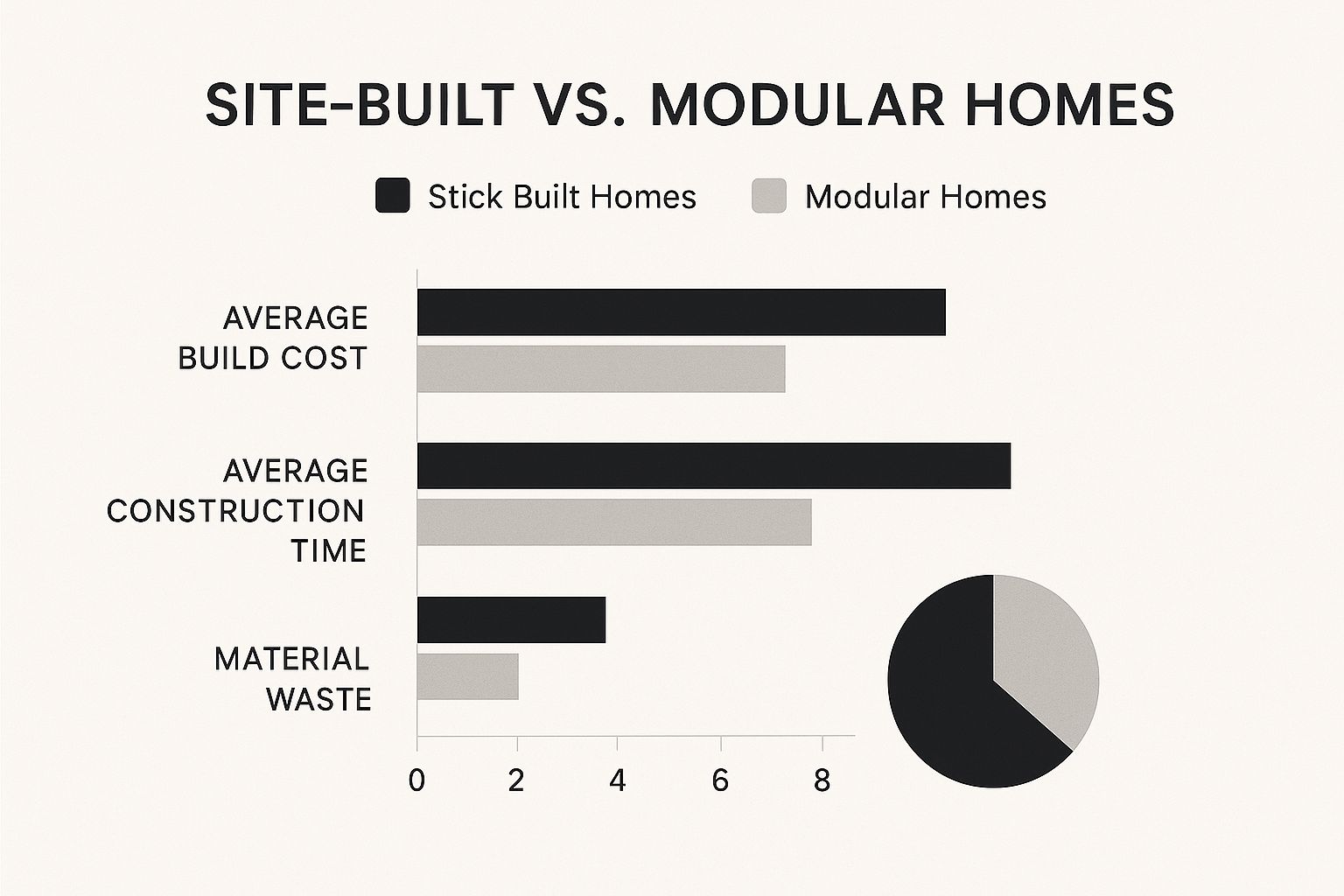

At a Glance Cost and Timeline Comparison

This table breaks down the essential financial and scheduling factors, giving you a clear snapshot of what to expect from each construction method.

| Factor | Stick-Built Homes (On-Site Construction) | Modular Homes (Factory Construction) |

|---|---|---|

| Initial Cost | Can be lower upfront but is more of an estimate. | Often seems higher but is more inclusive and fixed. |

| Final Budget | Prone to overages due to delays, changes, and material price shifts. | Highly predictable; cost overruns are rare. |

| Construction Time | Typically 8-12+ months, sequential and weather-dependent. | Typically 4-6 months, with parallel site and factory work. |

| Financing | Standard construction loans are widely available. | Requires a construction-to-permanent loan; some lenders are less familiar. |

| Material Waste | Higher, with an average of 10-15% waste generated on-site. | Significantly lower, often less than 2%, due to factory precision. |

Ultimately, both approaches have their place, and the "better" option really depends on your specific needs and priorities for your new home.

The SEGC Approach to Value and Efficiency

As a Native American-owned, 8(a), and HUBZone certified firm, our mission is simple: deliver outstanding value and build unwavering trust, no matter which construction path you take. We use our deep local experience to make every project run smoothly.

- For Stick-Built Projects: We run a tight ship with rigorous scheduling and rely on our long-standing relationships with the best subcontractors in the Lumberton and Fayetteville areas to minimize delays.

- For Modular Projects: We partner with only the best factories and handle the complex logistics of getting modules from the factory to your foundation with military precision.

At the end of the day, both methods can result in a beautiful, high-quality home. The real question is, what do you value more? The speed and certainty of a streamlined process, or the creative freedom that comes with a traditional on-site build?

Quality and Customization: The Great Debate

Let's get right into one of the biggest myths in the stick-built vs. modular homes conversation. There's this stubborn idea that "factory-built" is just a nice way of saying "lower quality," while "on-site" automatically means superior craftsmanship. The reality is way more interesting than that.

The truth? Both methods can build you an absolutely stunning, high-quality home. The real difference isn't about good vs. bad; it's about the process of getting there and how much you can personalize it. One is all about precision engineering in a controlled setting, while the other is about pure, unbridled artistic freedom on your land.

The Precision Engineering of Modular Homes

Modern modular home factories are truly something to see. Think about it: a home built entirely shielded from North Carolina's wild weather. No rain-soaked lumber, no materials baking in the summer sun, and absolutely zero weather delays. Everything is assembled with precision jigs and tools that you just can't drag out to a muddy construction site.

This controlled environment creates a consistency that's tough to match in the field. Inspections happen at every single stage of the build, making sure every wire, pipe, and joint is perfect before a module ever hits the road. The final product is a home with incredible structural integrity and uniformity.

As a builder with over 21 years of experience, we've seen how a well-run factory can produce an incredibly tight, energy-efficient, and durable home. Quality isn't about where it's built; it's about the standards and integrity of the people building it.

The Boundless Freedom of Stick-Built Homes

While modular homes nail precision, stick-built construction is king when it comes to pure, no-holds-barred customization. If you can dream it up, a good on-site builder can bring it to life. There are simply no limits on architectural style, complex floor plans, or one-of-a-kind design features.

Want a soaring two-story great room with a massive curved wall of windows? Or a complex roofline designed to catch the perfect morning light? A stick-built home is your blank canvas. This method also leaves room for a little on-the-fly creativity, letting you make small changes as you watch your vision come together on your own property. It’s a much more organic and collaborative journey.

A Lumberton Legacy: The Power of Personalization

To really understand the impact of this freedom, you just have to look at a recent project we completed in Lumberton. A family came to us with a gorgeous, but unique, piece of land and a vision that was anything but cookie-cutter. They needed exact room dimensions for heirloom furniture, a custom workshop built right into the house, and a massive porch big enough for the whole extended family.

Their dream home just couldn't be built in pieces. It demanded the hands-on artistry of our on-site crews to work with the land's unique grade and make their deeply personal vision a reality.

- Adapting to the Land: We were able to tweak the foundation and framing in real-time to save mature trees and maximize the best views.

- Integrating Unique Features: The workshop was seamlessly built into the home’s structure, something that would've been a huge headache for a modular design.

- Achieving Architectural Detail: The family wanted specific exterior stonework and timber accents that could only be done with meticulous on-site craftsmanship.

This project is the perfect example of why stick-built is still the only choice for people who refuse to compromise on personalization. They weren’t just building a house; they were crafting a family legacy. That kind of work requires the flexibility you only get from building on-site. As a Native American-owned firm committed to building legacies, we were honored to guide them through that process and make sure every detail told their family's story.

Getting the Keys: Financing and Future Value

Let's talk money. Figuring out the financing for your new home can feel like a bigger job than building the thing itself. When you're weighing stick-built against modular, you need to know how banks see them and what your investment will look like years from now.

Getting a construction loan is your first big step, and while it's a familiar path for both types of homes, there are a few twists in the road.

Lenders know the stick-built process like the back of their hand. It's a classic setup where they release funds as work gets done on-site—pour the foundation, get a check; frame the walls, get another. Easy peasy. For modular homes, you’ll typically be looking at a construction-to-permanent loan. This loan covers the factory build first and then rolls into a regular mortgage once your home is set on its foundation. It’s becoming more popular, but not every lender is up to speed, which makes it incredibly important to have a builder who already has solid relationships with banks that get it.

Making Homeownership Happen

Here’s where a big difference really shows up, especially for first-time buyers in places like Fayetteville and Lumberton. Government-backed loans, like FHA and VA loans, are game-changers. They’re designed to be more accessible, with lower down payments and more forgiving credit requirements, putting a new home within reach for a lot of families.

Modular homes are practically tailor-made for these kinds of loans because their costs and schedules are so predictable. In fact, one study found something pretty telling: 38.6 percent of modular buyers used FHA or VA loans. That’s double the rate for stick-built homebuyers. It just goes to show that the efficiency and affordability of modular construction are a perfect match for many people. You can read more about how modular construction helps address housing needs on urban.org.

The Real Secret to Long-Term Value

Okay, you've moved in. Now what? The big question shifts from getting a loan to protecting your investment for the future. There’s a stubborn myth that one building method holds its value better than the other, but it's just not true. A high-quality modular home, secured to a permanent foundation, appraises and appreciates exactly like a comparable stick-built house. To the market, a home is a home.

So what’s the one thing that truly guarantees a strong resale value? It’s not how it was built, but who built it.

We’ve been building legacies in North Carolina for over 21 years, and we can tell you this for certain: quality is the only currency that matters. A home built with an obsessive eye for detail, top-notch materials, and a serious commitment to durability will always be a great investment, whether its walls went up on your lot or in a factory.

The builder’s reputation and their passion for the craft are what turn four walls and a roof into a valuable, lasting asset. A home that’s built right will always attract buyers and fetch a better price down the road. That’s why picking your builder is the single most important financial decision you’ll make. Our guide on how to choose a general contractor is a great place to start.

As a Native American-owned, 8(a), and HUBZone certified firm, we don't just build homes—we build trust. We make sure every project, whether it's stick-built or modular, is an investment that will serve your family for generations to come.

So, Which Building Path Is Right for Your Family?

Deciding between a stick-built and a modular home isn't really about picking a "winner." It's about figuring out which path best fits your family's story, your land, and your life right now. The whole stick-built vs. modular debate gets a lot clearer when you move past generic pros and cons and start thinking about your actual needs. My goal here is to give you context, not just a list of facts, so you can walk away feeling confident.

As a Native American-owned firm, we've spent over 21 years helping families in Fayetteville and Lumberton build their legacies. We’ve been in the trenches for this exact decision countless times, and if there's one thing we've learned, it's that every family, every piece of land, and every dream is completely different.

Let's Look at Some Real-World Scenarios

To make this less abstract, let's walk through a couple of common situations. See if one of these sounds a little like you.

Scenario 1: The Visionary with a Tricky Piece of Land

Imagine you're a family in Fayetteville who found a gorgeous, but steep, sloped lot overlooking a creek. You have a very specific vision: complex rooflines, a massive curved wall of windows, and a deck that seems to float out from the hillside. You're ready to invest the time to make sure every single detail is perfect.

- Our Take: This has custom stick-built home written all over it. The on-site process gives you the flexibility to adapt the foundation to that tricky terrain and bring a truly unique design to life. The hands-on, piece-by-piece nature of a stick-built project is what allows for the kind of architectural artistry your vision requires.

Scenario 2: The First-Time Homebuyer on a Tight Timeline

Okay, now picture this: you're a young family in Robeson County, thrilled to be building your first home. Predictability is everything. You have a hard budget and an even harder move-in date before the new school year kicks off. You want a beautiful, well-built home without the stress of weather delays or surprise costs popping up.

- Our Take: A modular home is probably your best bet. The factory-controlled environment gives you a predictable timeline and a fixed price, which takes a huge amount of anxiety off the table. You get a high-quality, energy-efficient home built fast, letting your family settle in without the rollercoaster of a long, uncertain on-site build.

At South Eastern General Contractors, we've always believed the right choice starts with the right partner. Our job isn't to push one construction method over another; it's to listen to your goals and act as your trusted advisor while you build your legacy.

The Right Partner is the Real Secret

At the end of the day, whether your home’s walls go up in a factory or on your homesite isn't what makes or breaks the project. The success of your build comes down to the integrity, skill, and commitment of the builder you hire. The right team will guide you through the entire journey with total clarity and confidence.

We'd love to sit down and just talk about your vision. Let's get past the numbers for a minute and discuss the legacy you want to build. Getting familiar with the nuts and bolts is important, and our guide to the custom home building process is a great place to start. As an 8(a) and HUBZone certified firm, we’re deeply committed to serving our community and building relationships that last a lifetime.

Questions We Hear All the Time

Choosing between a stick-built home and a modular one is a big decision, and you’ve probably got a lot of questions. After 21+ years of building homes for families here in Fayetteville and Lumberton, we've pretty much heard them all. Here are the straight-up answers we give our clients every day.

So, Are Modular Homes Actually Cheaper?

Not necessarily, but they are often more predictable. The base price for a modular home can be lower per square foot because building in a factory is just plain efficient. But once you start adding high-end customizations and factoring in site work, the final price tag can easily match a traditional stick-built home.

The real win here is cost certainty. With a modular build, your price is locked in early on. You won't get those nail-biting phone calls about unexpected lumber costs or weather delays throwing your budget for a loop.

Do They Appreciate Like a "Real" House?

Yep. One hundred percent. A modular home set on a permanent foundation is, for all intents and purposes, a "real" house. Appraisers treat it the same, banks treat it the same, and the market treats it the same. The old myth about them losing value comes from a mix-up with mobile homes, which are a completely different animal.

"A home's value isn't tied to how it was built, but how well it was built. Quality craftsmanship and a builder you can trust—that's what makes a great long-term investment. Period."

Wait, Aren't Modular and Manufactured Homes the Same Thing?

Nope, not even close. It's a common point of confusion, so let's clear it up.

- Manufactured Homes: You might know them as mobile homes. They're built on a permanent steel frame (the chassis) and have to follow a federal code from HUD.

- Modular Homes: These are built to the very same local and state building codes as any stick-built house. Once the sections are brought to your land and pieced together on a permanent foundation, you can't tell the difference.

Can I Even Get a Normal Loan for a Modular Home?

Absolutely. Financing for a modular home is common, though the structure is a little different. Most people get a construction-to-permanent loan. This loan covers the cost of building the home in the factory and getting it set up on your land, then it rolls right into a standard mortgage once you move in.

As an 8(a) and HUBZone certified firm with deep roots in North Carolina, we have great relationships with local lenders who know this process inside and out and can make it smooth for you.

Which One Is Tougher? Stick-Built or Modular?

When done right, both are built like a fortress. A modular home has a few unique advantages—it’s built with machine precision in a climate-controlled factory, so the materials never get rained on. Plus, each module has to be sturdy enough to be trucked down the highway, so they are often over-engineered for strength.

Stick-built homes, on the other hand, have stood the test of time for centuries, relying on the expertise of skilled builders on-site. The truth is, a home's durability comes down to one thing: the builder's commitment to doing the job right.

At South Eastern General Contractors, we’re not just putting up walls; we’re building legacies. Whether you're dreaming of a fully custom stick-built home or a beautifully efficient modular design, our team is here to help you make it happen with the trust and quality we've delivered in Fayetteville and Lumberton for over two decades. Let's start the conversation about your future home. Schedule a consultation with us today.