What is rough in plumbing: Quick guide to avoid mistakes

Ever ripped open a wall during a remodel and stared at that wild maze of pipes? That, my friends, is rough-in plumbing. It's the skeleton of your home's water and waste system, the unsung hero that gets installed long before any drywall goes up. As a Native American-owned, 8(a), and HUBZone certified firm with deep roots in Fayetteville and Lumberton, we at SEGC believe understanding this stage is key to appreciating true quality construction.

Your Home's Unseen Plumbing Blueprint

Think of it like the body's circulatory system. The rough-in phase is when we carefully install all the arteries and veins—the water supply lines, drain pipes, and vents—that will eventually feed your fixtures. We're not hooking up that shiny new faucet or installing the toilet just yet. That's for the "finish plumbing" stage.

Right now, it’s all about the strategic, behind-the-scenes work. We're making sure water gets where it needs to go and waste has a clear, safe path out. For our clients here in the Fayetteville and Lumberton communities, understanding this part of the process is crucial. It’s where true quality is built into a home. Every single pipe's location and angle is meticulously planned, much like knowing how to read construction blueprints is the key to the entire build.

At SEGC, we believe the rough-in phase is a promise. It’s the promise of a functional, problem-free home, where our dedication to quality begins long before the beautiful finishes ever arrive on site. It's how we build client trust from the ground up.

Getting this stage absolutely perfect is non-negotiable. One mistake here can lead to leaks, clogs, and jaw-dropping repair bills down the road. It's no surprise the global plumbing fixtures market was valued at a staggering $89.8 billion in 2023. That number shows just how much homeowners and builders invest in reliable plumbing, and it all starts with a flawless rough-in.

This foundational work demands an expert's precision, which is a cornerstone of our process at SEGC. Our 21+ years of proven results have taught us that the painstaking approach ensures the unseen network behind your walls is built to a standard that creates legacies, not just structures. It’s how we’ve earned our reputation as a local leader.

Rough-In Plumbing Vs Finish Plumbing At A Glance

It’s easy to get these two stages mixed up. Let's clear the water with a quick comparison of what happens when. Think of rough-in as the "behind-the-wall" work and finish as the "in-your-face" stuff you see and use every day.

| What Rough-In Plumbing Includes | What Finish Plumbing Includes |

|---|---|

| Installing drain, waste, and vent pipes (DWV) | Connecting and installing sinks and faucets |

| Running hot and cold water supply lines | Setting toilets and hooking up water supply |

| Setting tub and shower bodies/valves | Installing showerheads and tub spouts |

| Stubbing out pipes through walls and floors | Attaching garbage disposals and dishwashers |

| Capping all lines for pressure testing | Connecting washing machine supply lines |

| No fixtures, just the connections for them | All visible and usable plumbing components |

Essentially, the rough-in lays the groundwork, and the finish work brings it all to life. Once the rough-in is inspected and approved, the walls can be closed up, and you're one step closer to a finished home.

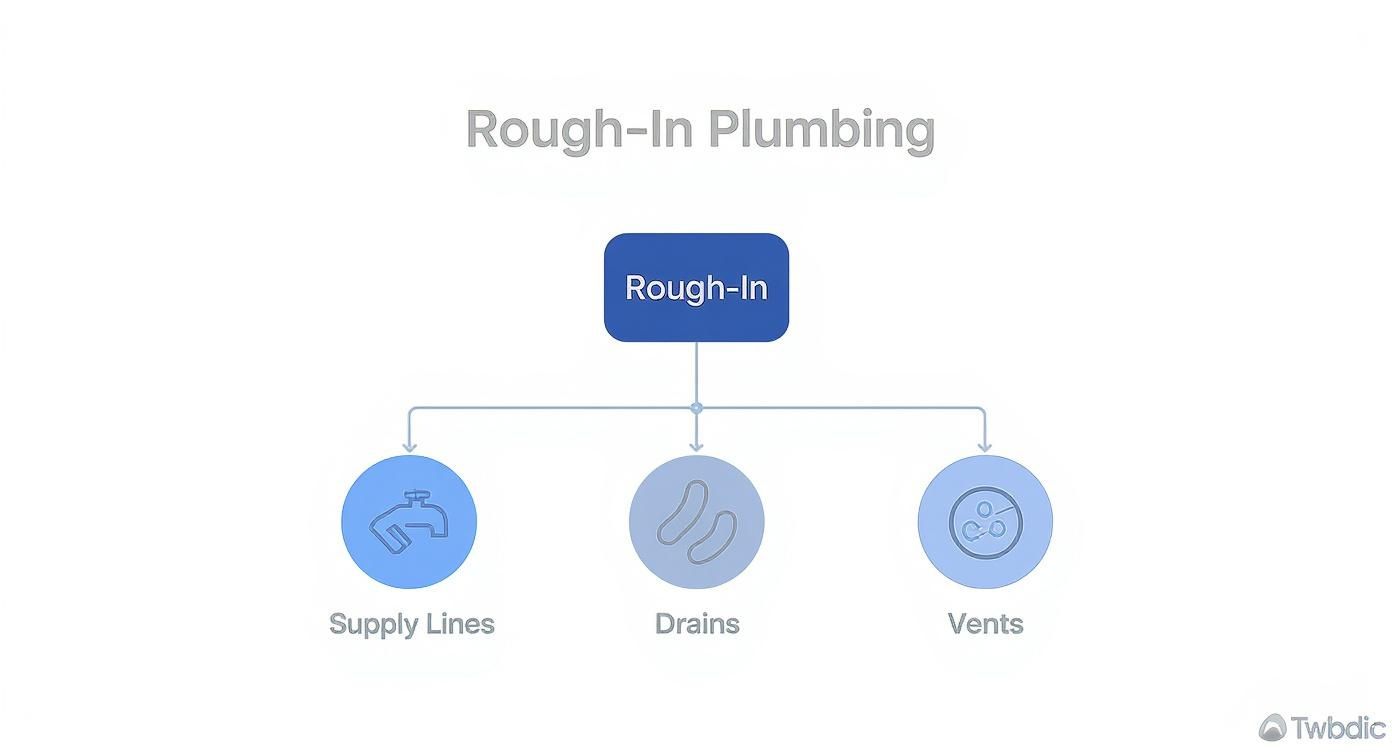

The Three Core Systems Of A Plumbing Rough-In

Think of your home’s plumbing as a tree, with its most important parts hidden inside your walls. A proper rough-in is like building that tree from the ground up, making sure every branch and root is perfectly placed before you close everything up. It’s a complex dance of three interconnected systems, all working together to handle every drop of water in your house.

After more than 21 years of getting our hands dirty on job sites in communities like Fayetteville and Lumberton, we at SEGC have this process down to a science. It's about more than just pipes; it's about making sure your home's circulatory system is flawless from day one, an actionable insight that builds client trust.

Let's break down those three core systems. Seeing how they connect makes the whole "rough-in" concept click.

As you can see, a solid rough-in isn't just one big network. It's a careful balancing act between bringing clean water in, getting used water out, and letting the whole system breathe.

Drain-Waste-Vent (DWV) System

This is the big one—the trunk and main branches of our plumbing tree. The Drain-Waste-Vent (DWV) system is the unsung hero of your home, quietly and safely escorting all the wastewater and solids outside.

- Drains: These are the pipes you see under your sink or connected to your shower. They're the on-ramps for used water.

- Waste Lines: Think of these as the main highways. All the smaller drain pipes merge into these larger lines, which carry everything to the city sewer or your septic tank.

- Vents: This is the clever part. Vents don't carry any water at all. They run up through your roof, allowing air into the system. This equalizes the pressure, so your drains flow smoothly (no gurgling!) and, most importantly, prevents nasty sewer gases from bubbling back into your home.

Honestly, without a perfectly mapped DWV system, your plumbing just plain fails. It's the absolute foundation, and it's something we take massive pride in getting right every single time. As a local leader in construction, we know our community's trust is built on this commitment to quality.

A crucial element of any effective plumbing rough-in for basement drainage is the inclusion of a sump pump. Understanding the associated costs is key when planning your project; learn more about typical sump pump installation prices.

Water Supply Lines

If the DWV system is all about getting the bad stuff out, the water supply lines are the roots bringing the good stuff in. This network is a bit simpler, usually consisting of two parallel lines—one for hot and one for cold—that snake from your main water source to every spot that will eventually need water.

During the rough-in phase, we run all these lines, secure them tightly, and then cap them off. This lets us pressurize the whole system to test for even the tiniest leaks before a single sheet of drywall goes up. It's a non-negotiable quality check and a core part of our mission to build legacies, not just structures.

Stub-Outs

Finally, we have the stub-outs. These are the only parts of the rough-in you can actually see when we're done. They're the little capped ends of pipe poking through the wall studs, patiently waiting for the plumber to come back and install the sink, toilet, or washing machine.

Getting the stub-outs in the exact right spot is a mark of a true pro. It takes foresight and precision, ensuring that when it's time to install the fixtures, everything lines up perfectly.

Finding The Perfect Window For Plumbing Rough In

Think of a construction project like a meticulously planned concert. Every musician—the framers, the electricians, the plumbers—has a precise moment to step into the spotlight. For plumbing rough-in, that moment is a golden window of opportunity, and the timing has to be just right.

This critical phase kicks off right after the home’s skeleton—the framing—is complete, but before any insulation or drywall goes up. It’s the "open-wall" stage, a beautiful, brief period where plumbers, electricians, and HVAC techs have a free-for-all, unobstructed playground to run pipes, wires, and ducts through the wall cavities and floor joists.

The Symphony of Trades

It’s all about timing. The plumbing crew has to work in perfect harmony with everyone else on site. A drainpipe for the upstairs shower can't fight for the same space an HVAC duct needs to occupy. This is where a sharp general contractor truly earns their keep, especially on the kind of complex jobs we handle across Fayetteville and Lumberton.

"Precise scheduling isn't just a suggestion; it's non-negotiable. At SEGC, we don't just build structures; we conduct a symphony. Our 21+ years of experience means we know what every trade needs before they even ask, making sure the rough-in phase flows smoothly without expensive delays or do-overs." – An SEGC Project Manager's Insight

As an 8(a) and HUBZone certified firm, our project management isn't just a skill—it's an art form. We get our plumbing teams talking with the other contractors, creating an environment where everyone can do their best work without tripping over each other. That kind of seamless coordination is exactly how we've built so much trust in the community.

Why The Timing Is So Crucial

Getting the rough-in done during this open-wall stage isn’t just about making life easier; it's fundamental to quality and safety. It’s the only chance to give every single connection, joint, and pipe a thorough once-over before they're buried behind a wall, potentially for decades.

Here’s why that window is so vital:

- Inspection Access: A building inspector needs to physically see everything to sign off on it. They’ll be checking for proper drain slopes, making sure pipes are supported correctly, and verifying that all the vents are in the right place to meet code.

- Pressure Testing: Before the walls are closed, the water supply lines are filled with either air or water under high pressure. This is how we hunt for leaks. Finding and fixing a tiny pinhole leak at this stage is a five-minute job. Finding it after the walls are painted? That’s a nightmare.

- Clash Detection: It's a real-life game of Tetris. With the walls open, everyone can see where the other trades have been, preventing that awful moment when an electrician accidentally drills right through a brand-new water line.

This meticulous, perfectly-timed approach is all about preventing future headaches. It ensures the hidden guts of your building are solid, secure, and built with the integrity that reflects our mission: building legacies that last.

Passing The All-Important Rough-In Inspection

Let's be clear: a plumbing rough-in isn't really done until it gets the official nod from a city or county building inspector. This isn't just a bureaucratic hoop to jump through. It's the critical quality check that confirms the complex web of pipes hidden behind your walls is safe, sanitary, and built to stand the test of time.

For a homeowner, that green tag from the inspector is the ultimate peace of mind.

The inspection itself is a detailed affair. The inspector will walk the site, verifying that every single pipe is the right size for the job, each drain has the perfect slope to let gravity do its work, and all the lines are strapped down tight.

But the main event? The pressure test. The entire system is pressurized with air or water to prove beyond a shadow of a doubt that there are zero leaks. This is where craftsmanship really comes into play, and for our Native American-owned firm, passing on the first try is a point of professional pride.

What Inspectors Look For

While the fine print might change a bit from one town to the next, every inspector is on the hunt for the same things: safety, function, and long-term reliability. They’re making sure the system will work flawlessly for decades.

Here’s what’s on their checklist:

- The Goldilocks Slope: Drain lines need to be angled just right—usually a quarter-inch of drop for every foot of pipe. If it's too steep, the liquids can outrun the solids (you can imagine the result). Too shallow, and you're setting the stage for future clogs.

- Solid Support: Nobody wants to hear pipes rattling around in the walls years from now. The inspector makes sure every pipe is properly strapped and supported to prevent sagging and noise.

- Proper Venting: This is a big one. They verify that every fixture has a clear path for air, which prevents nasty sewer gases from entering your home and ensures your drains flow smoothly.

- The Leak Test: This is the final boss. The system has to hold a specific pressure for a set period. Any drop, no matter how small, means a leak somewhere, and that's an automatic fail.

Local Project Story: On a recent custom home we built in Lumberton, our team's obsessive attention to detail meant we sailed through the rough-in inspection on the first attempt. For the client, this didn't just save a few days on the schedule; it prevented the kind of hidden problems that can turn into major headaches down the road. That's how you build trust—by getting it right the first time.

When you look at the numbers, the rough-in plumbing phase can represent 20-30% of the total plumbing budget for a new home. With that much of your investment about to be sealed up in the walls, you can't afford to get it wrong. Passing the inspection without the need for expensive and time-consuming rework is crucial for keeping a project on budget.

This milestone requires the same focus as getting ready for the electrical inspection, where every connection and placement is scrutinized. To get a feel for how detailed these checks are across different trades, take a look at our electrical rough in inspection checklist. At SEGC, our 8(a) and HUBZone certified teams don't just build structures; we build legacies founded on proven results.

How To Avoid Common Rough In Plumbing Disasters

Let me tell you something: even the tiniest misstep during the plumbing rough-in phase can balloon into an absolute monster of a problem down the road. I'm talking about drains that gurgle in protest, hidden leaks that turn your brand-new wall into a moldy, rotten mess, and phantom sewer smells that you just can't seem to shake.

After 21+ years in this business, trust me, we've seen every shortcut and blunder you can imagine.

Some of the classic mistakes sound almost trivial, but their consequences are massive. Getting the drain slope wrong by even a fraction of an inch? You’ve basically just guaranteed a future full of clogs. Forgetting a critical vent pipe or installing it improperly? Get ready for drains that glug and bubble, and an aroma you definitely didn't ask for.

The SEGC Solution To Common Pitfalls

This is where experience really pays off. For every common industry blunder, we’ve developed a rock-solid prevention method. As a Native American-owned firm with deep roots right here in Fayetteville and Lumberton, we've built our reputation on getting the bones of a building right.

Our technicians are trained to be meticulous. They don’t just eyeball it—they double-check every slope, pressure-test every joint, and protect every single pipe from the chaos of a busy construction site. It's not just about meeting code; it's about building something that lasts.

This kind of foresight is more than just good practice; it's central to our mission of building legacies. To see how this nitty-gritty detail fits into our overall promise of quality, you should check out our comprehensive construction quality assurance checklist.

"A flawless rough-in is invisible. You'll never see it, but you'll feel it every time you use a sink that drains perfectly or enjoy a home free of mysterious plumbing issues. That invisibility is our measure of success."

Knowing what can go wrong is half the battle. When a rough-in is botched, the homeowner is often the one left calling for professional water leakage repair services years later to clean up the mess. Our entire process is designed to make sure our clients never have to make that call.

We put together this quick table to show you the difference between a job that just "passes" and a job done the right way.

Common Rough In Pitfalls Vs The SEGC Standard

| Common Mistake | Potential Problem | The SEGC Prevention Method (Actionable Insight) |

|---|---|---|

| Incorrect Drain Slope | Frequent clogs and backups. Water just sits in the pipes instead of flowing away. | We use laser levels and digital tools to lock in a perfect ¼-inch per foot slope on all horizontal drain lines. No guesswork, just gravity doing its job. |

| Improper Pipe Support | Rattling noises in the walls, sagging pipes that create low spots and lead to blockages. | We don't just meet code for pipe strapping—we exceed it. We use high-quality supports to secure every line firmly so it's silent and stable for decades. |

| Damaged Pipes | Pinhole leaks from a stray nail or screw, causing slow-burn water damage, rot, and mold behind the drywall. | All our stub-outs are fitted with protective guards. We also coordinate like crazy with other trades to make sure our pipes are a "no-go" zone for their tools. |

It's this dedication to craftsmanship that has earned us our reputation for proven results. Our 8(a) and HUBZone certified teams get it: excellence isn't something you add at the end. It’s built into the very bones of the structure, long before the first coat of paint goes on the walls. It’s why our clients don't just hire us to build projects; they trust us to build their future.

Got Questions About Your Plumbing Rough-In? We've Got Answers.

Let's be honest, "plumbing rough-in" isn't exactly a term you hear every day. So, when it comes up in your construction project, it’s natural to have a few questions. We’ve heard them all, and we're here to clear things up so you can feel totally empowered and in the loop.

How Long Does The Plumbing Rough-In Take For A New House?

For a standard single-family home, you can expect the plumbing rough-in to take about 3 to 5 days. That's our target.

Of course, this isn't set in stone. The timeline can stretch a bit depending on the complexity of the job—think a sprawling floor plan, multiple kitchens, or a bathroom for every bedroom. The real key, though, is how smoothly we can dance with the other trades on site. As seasoned general contractors in Fayetteville and Lumberton, SEGC are masters of project choreography, making sure everything flows without ever sacrificing an ounce of quality.

Can I Change My Bathroom Layout After The Rough-In Is Done?

In a word? Please don't. While anything is technically possible with enough time and money, changing your mind after the pipes are in is a recipe for a headache.

Think about it: we'd have to start tearing open freshly installed walls, ripping out pipes, and rerouting everything. It’s messy, expensive, and a surefire way to derail your project's timeline.

This is exactly why we insist on finalizing your layout before a single pipe is cut. At SEGC, our process is built around a meticulous plan review to make absolutely certain your vision is locked in, saving you from costly do-overs down the road. This proactive step is an actionable insight into how we protect our clients' budgets and timelines.

Should I Try To DIY My Own Plumbing Rough-In?

We love a can-do attitude, but this is one of those jobs you absolutely want to leave to the pros. Plumbing rough-in is a different beast entirely from swapping out a faucet. It’s a complex puzzle of drain slopes, vent systems, and supply lines that all have to meet strict local building codes.

One wrong move—a pipe sloped at the wrong angle or a vent in the wrong place—can lead to nasty clogs, sewer gas leaks, and a big, fat "FAILED" stamp from the building inspector. Even worse, it could cause hidden water damage inside your walls.

Hiring a certified and experienced firm like SEGC is your insurance policy. It guarantees the work is done right the first time, safely, and up to code. As a Native American-owned, 8(a), and HUBZone certified company, we don’t just build structures; we build legacies. You can trust that the hidden plumbing foundation of your home is rock-solid.

At South Eastern General Contractors, our commitment to quality is built into every project from the very first pipe. With 21+ years of proven results as local leaders in Fayetteville and Lumberton, we don’t just build structures—we build legacies. If you’re ready to partner with a team you can trust, let's start the conversation. Visit us online to explore our work and see what makes us different at https://www.southeasterngc.com.